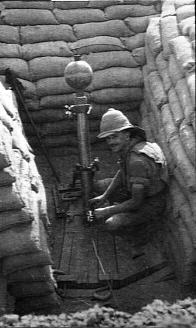

2-inch medium mortar

[11] This was the first design to meet all the requirements, after modifications to simplify manufacture; it fired a good-sized spherical cast-iron bomb of 42 lb (19 kg) (total projectile weight 51 lb (23 kg) with stick and fuze), considered the largest practical size for use from trenches, at ranges from 100 to 600 yd (91 to 549 m) using a simple 2-inch tube as the mortar body.

The mortar and ammunition could be cheaply manufactured by small unsophisticated "trade" workshops; the bomb was safely detonated by a standard No.

Drawbacks were that the steel tail was usually projected backwards towards the firer when the bomb detonated, resulting in occasional casualties and the No.

The short range was a disadvantage as it could only be used if no man's land (between the British and enemy front line) was relatively narrow.

It was used to fire some white star (50%-50% chlorine and phosgene) gas bombs during the Battle of the Somme[18] until other specialised longer range projectors became available.

The Royal Artillery had a higher priority in receiving the already insufficient number of tubes so ignition was changed to use a Lee–Enfield bolt mechanism and chamber screwed into a socket in the barrel near the base.

[3][19] A special blank rifle cartridge was loaded and fired via a lanyard from a sheltered position if possible due to the risk of bombs falling short.

[14] Estimated rounds required for various targets, with instantaneous percussion fuze 107:[20] Provision was made in mid-1916 for attachment of the "Temple silencer" at the muzzle,[3] intended to reduce the flash and noise generated on firing, which at the short ranges the mortar operated at was quickly noticed by the enemy and invited artillery response.

[6] In Spring 1918 many of these obsolescent bombs were buried on the Western Front under metal plates as anti-tank mines in expectation of attack by German tanks.