3D printing speed

Changing the orientation of a part can be done through either the STL file or on the CAD model, or in the slicer before generating the gcode.

Determining the optimal part orientation is a common software solution for all additive manufacturing processes.

This can lead to a significant improvement in many key factors that affect the total print time.

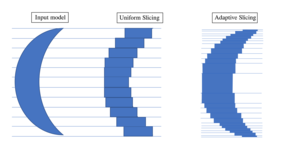

By adaptively computing the height distribution of layers, this error can be minimized: The quality of surface increases while post-processing time decreases.

Depending on the technology used, there are some challenges that could limit the speed of the 3D printing: Interesting features of sound waves have encouraged scientists to use it in additive manufacturing.

The fact that it can be applied over a large area at the same time makes it a good candidate for rapid fabrication.

Then the acoustic mask is used to generate the desired pressure sound field to put the particle in the correct order.

Moreover, by controlling the intensity of each pixel in the setup topographical patterning can be created in a single exposure with no stage translation.

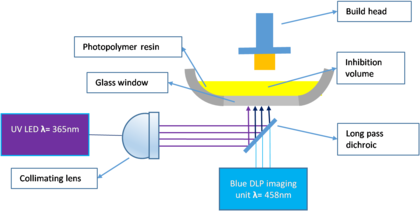

[13] Rapid, large-volume, thermally controlled 3D printing, using a mobile liquid interface Another way to address the adhesion problem is to create a dead layer which prohibits the curing process.