Fused filament fabrication

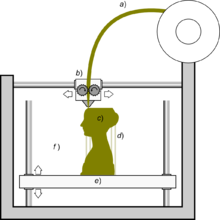

[1] Filament is fed from a large spool through a moving, heated printer extruder head, and is deposited on the growing work.

The speed of the extruder head may also be controlled to stop and start deposition and form an interrupted plane without stringing or dribbling between sections.

"Fused filament fabrication" was coined by the members of the RepRap project to give an acronym (FFF) that would be legally unconstrained in its use.

A wide variety of filament materials are extruded, including thermoplastics such as acrylonitrile butadiene styrene (ABS),[4] polylactic acid (PLA), polyethylene terephthalate glycol (PETG), polyethylene terephthalate (PET), high-impact polystyrene (HIPS), thermoplastic polyurethane (TPU) and aliphatic polyamides (nylon).

[6][7] With the 2009 expiration of the patent on this technology,[8] people could use this type of printing without paying Stratasys for the right to do so, opening up commercial, DIY, and open-source (RepRap) 3D printer applications.

Myriad materials are available, such as Acrylonitrile Butadiene Styrene (ABS), Polylactic acid (PLA), Polycarbonate (PC), Polyamide (PA), Polystyrene (PS), lignin, rubber, among many others, with different trade-offs between strength and temperature properties.

Operating the FFF process within an inert gas atmosphere such as nitrogen or argon can significantly increase the layer adhesion and leads to improved mechanical properties of the 3D printed objects.

During extrusion the thermoplastic filament is introduced by mechanical pressure from rollers, into the liquefier (or hotend), where it melts and is then extruded.

The system continuously adjusts the power supplied to the coils according to the temperature difference between the desired value and the value detected by the thermocouple, forming a negative feedback loop.

[28] FFF is also applied in manufacturing within other sectors, including aerospace, automotive, construction, electronics, energy, pharmaceuticals, sports, textiles, and toys.

The RepRap project aims to produce a free and open source hardware (FOSH) 3D printer, whose full specifications are released under the GNU General Public License, and which is capable of replicating itself by printing many of its own (plastic) parts to create more machines.

[35][36] Customer-driven product customization and demand for cost and time savings have increased interest in agility of manufacturing process.

[39] The open source Fab@Home project[40] has developed printers for general use with anything that can be extruded through a nozzle, from chocolate to silicone sealant and chemical reactants.

Printers following the project's designs have been available from suppliers in kits or in pre-assembled form since 2012 at prices in the US$2,000 range.

The LulzBot 3D printers manufactured by Aleph Objects are another example of an open-source application of fused deposition modeling technology.

These kits come complete with all parts needed to make a functioning printer, often including electronic files for test printing as well as a small quantity of PLA filament.

Additionally, fluoropolymers such as PTFE tubing are used in the process due to the material's ability to withstand high temperatures.

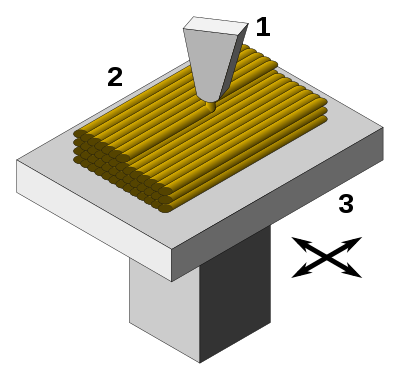

Several material classes can be extruded and 3d printed: The majority of fused filament printers follow the same basic design.

As, unlike laser cutters, head movement speeds are low, stepper motors are universally used and there is no need to use servomotors instead.

These are typically printed connector blocks with a variety of angled holes, joined by cheap steel threaded rod.

This makes a construction that is cheap and easy to assemble, easily allows non-perpendicular framing joints, but does require access to a 3D printer.

The lack of stiffness in the rod also requires either triangulation, or gives the risk of a gantry structure that flexes and vibrates in service, reducing print quality.

Although it is an easy task for a robot's motion planning to convert from Cartesian to polar coordinates, gaining any advantage from this design also requires the print slicing algorithms to be aware of the rotational symmetry from the outset.

These informal standards include:[14] A different approach is taken with 'Rostock' or 'Kossel' pattern printers, based on a delta robot mechanism.

Stability and freedom from vibration when moving a heavy print head on the end of spindly arms is a technical challenge though.