Apollo/Skylab spacesuit

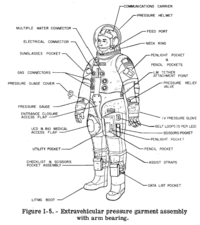

The Apollo SSA consisted of a Pressure Garment Assembly (PGA) and a backpack Portable Life Support System (PLSS).

After evaluation of the proposals, NASA preferred the Hamilton PLSS concept and program experience but the ILC PGA design.

By March 1964, Hamilton and NASA had found three successive ILC Apollo PGA designs to not meet requirements.

In comparative testing, only the David Clark Gemini suit was acceptable for Apollo Command Module use.

David Clark would provide the suits for the "Block I" early missions without extra-vehicular activity (EVA).

The later, longer-duration Apollo missions would be Block III and have more advanced pressure suits and a longer duration backpack to be provided by suppliers selected in future competitions.

[12] NASA subsequently terminated the Block II AiResearch backpack, thus completing the selection of the suit/backpack designs and suppliers to support man's first walking on the Moon.

Also in 1968, NASA recognized that with modifications, the Block II EMU could additionally support the later EVA missions that involved a Lunar Rover Vehicle (LRV).

The A7L is an evolution of ILC's initial A5L, which won a 1965 pressure suit competition, and A6L, which introduced the integrated thermal and micrometeoroid cover layer.

Quick disconnects at the neck and forearms allowed for the connection of the pressure gloves and the famous Apollo "fishbowl helmet" (adopted by NASA as it allowed an unrestricted view, as well as eliminating the need for a visor seal required in the Mercury and Gemini and Apollo Block I spacesuit helmets).

A cover layer, which was designed to be fireproof after the deadly Apollo 1 fire, was attached to the pressure garment assembly and was removable for repairs and inspection.

Between Apollos 7 and 14, the Commander (CDR) and Lunar Module pilot (LMP), had Torso Limb Suit Assemblies (TSLA) with six life support connections placed in two parallel columns on the chest.

[20] In late 1962, testing of an early training suit raised concerns about life support requirements.

The concerns were dismissed because the forthcoming Apollo new-designs were expected to have lower effort mobility and improved ventilation systems.

However, Hamilton took this as a strong indication that Apollo spacesuit life support requirements might significantly increase and initiated internally funded research and development in "backpack" technologies.

This would have been a great success but for the crewed testing confirming that the 1963 life support requirements were not sufficient to meet lunar mission needs.

These final increases required operational efficiencies that spawned the invention of the porous plate sublimator[21] and the Apollo liquid cooling garment.

Also deleted was the pressure relief valve in the sleeve of the suit and the tether mounting attachments which were used in the lunar module.

Over the TSLA, command module pilots wore only a three-layer Intravehicular Cover Layer (IVCL) of nomex and beta cloth for fire and abrasion protection.

The Extra-vehicular (EV) version was a new mid-entry suit that allowed greater mobility and easier operations with the lunar rover.

The A7LB EV suits were designed for longer duration J-series missions, in which three EVAs would be conducted and the Lunar Roving Vehicle (LRV) would be used for the first time.

Because of the waist joint, the six life-support connectors were rearranged from the parallel pattern to a set of two "triangles," and the up-and-down back zipper was revised and relocated.

NASA allowed a minor protrusion on one side for an auxiliary water tank resulting in the last configuration of backpack.

NASA elected to modify existing A7L EV units by simply removing the liquid cooling features to create a "new" A7LB CMP suit.

Because the J-series CSMs incorporated the Scientific Instrument Module (SIM) Bay, which used special film cameras similar to those used on Air Force spy satellites, and required a "deep space" EVA for retrieval, the CMP for each of the three J-series missions wore a five-connector A7LB-based H-series A7L suits, with the liquid cooling connections eliminated as the CMP would be attached to a life-support umbilical (like that used on Gemini EVAs) and only an "oxygen purge system" (OPS) would be used for emergency backup in the case of the failure of the umbilical.

To minimize program costs, NASA elected to fund ILC Dover for modifications to the mid-entry Apollo A7LB EV PSA design to reduce costs and use an umbilical system named the Astronaut Life Support Assembly (ALSA) to allow extra-vehicular activities.

The Skylab EMUs enabled emergency repair and outfitting tasks that permitted the program to conduct its long duration crewed missions and experiments.

Because of the short duration of those EVAs, and as a need to protect the delicate instruments, the Apollo lunar EVA backpack was replaced with an umbilical assembly designed to incorporate both breathing air (Skylab's atmosphere was 74% oxygen and 26% nitrogen at 5 psi) and liquid water for cooling.

For the Apollo–Soyuz Test Project, NASA decided to use the A7LB CMP pressure suit assembly worn on the J-missions with a few changes to save cost and weight since an EVA was not planned during the mission.

The changes included a simplified cover layer which was cheaper, lighter and more durable as well as the removal of the pressure relief valve and unused gas connectors.