Alternating current

Consumer voltages vary somewhat depending on the country and size of load, but generally motors and lighting are built to use up to a few hundred volts between phases.

When stepping down three-phase, a transformer with a Delta (3-wire) primary and a Star (4-wire, center-earthed) secondary is often used so there is no need for a neutral on the supply side.

Three-wire single-phase systems, with a single center-tapped transformer giving two live conductors, is a common distribution scheme for residential and small commercial buildings in North America.

This low impedance path allows the maximum amount of fault current, causing the overcurrent protection device (breakers, fuses) to trip or burn out as quickly as possible, bringing the electrical system to a safe state.

The original Niagara Falls generators were built to produce 25 Hz power, as a compromise between low frequency for traction and heavy induction motors, while still allowing incandescent lighting to operate (although with noticeable flicker).

[citation needed] Off-shore, military, textile industry, marine, aircraft, and spacecraft applications sometimes use 400 Hz, for benefits of reduced weight of apparatus or higher motor speeds.

[citation needed] A direct current flows uniformly throughout the cross-section of a homogeneous electrically conducting wire.

This measure helps to partially mitigate skin effect by forcing more equal current throughout the total cross section of the stranded conductors.

As written above, an alternating current is made of electric charge under periodic acceleration, which causes radiation of electromagnetic waves.

For microwave frequencies greater than 5 GHz, the losses (due mainly to the dielectric separating the inner and outer tubes being a non-ideal insulator) become too large, making waveguides a more efficient medium for transmitting energy.

The earliest recorded practical application of alternating current is by Guillaume Duchenne, inventor and developer of electrotherapy.

[4] Alternating current technology was developed further by the Hungarian Ganz Works company in the 1870s, and, in the 1880s, by Sebastian Ziani de Ferranti, Lucien Gaulard, and Galileo Ferraris.

In 1876, Russian engineer Pavel Yablochkov invented a lighting system where sets of induction coils were installed along a high-voltage AC line.

[5] In 1878, the Ganz factory, Budapest, Hungary, began manufacturing equipment for electric lighting and, by 1883, had installed over fifty systems in Austria-Hungary.

A bipolar open-core power transformer developed by Lucien Gaulard and John Dixon Gibbs was demonstrated in London in 1881, and attracted the interest of Westinghouse.

[citation needed] The inherent flaw in this method was that turning off a single lamp (or other electric device) affected the voltage supplied to all others on the same circuit.

In the UK, Sebastian de Ferranti, who had been developing AC generators and transformers in London since 1882, redesigned the AC system at the Grosvenor Gallery power station in 1886 for the London Electric Supply Corporation (LESCo) including alternators of his own design and open core transformer designs with serial connections for utilization loads - similar to Gaulard and Gibbs.

[12] In the autumn[ambiguous] of 1884, Károly Zipernowsky, Ottó Bláthy and Miksa Déri (ZBD), three engineers associated with the Ganz Works of Budapest, determined that open-core devices were impractical, as they were incapable of reliably regulating voltage.

[16] The ZBD patents included two other major interrelated innovations: one concerning the use of parallel connected, instead of series connected, utilization loads, the other concerning the ability to have high turns ratio transformers such that the supply network voltage could be much higher (initially 140 to 2000 V) than the voltage of utilization loads (100 V initially preferred).

[22] In early 1885, the three engineers also eliminated the problem of eddy current losses with the invention of the lamination of electromagnetic cores.

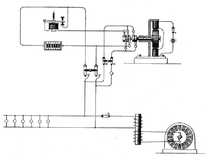

With this setup, the Westinghouse company successfully powered thirty 100-volt incandescent bulbs in twenty shops along the main street of Great Barrington.

[29][30] By the fall of that year Ganz engineers installed a ZBD transformer power system with AC generators in Rome.

A long-distance transmission of single-phase electricity from a hydroelectric generating plant in Oregon at Willamette Falls sent power fourteen miles downriver to downtown Portland for street lighting in 1890.

[36] The San Antonio Canyon Generator was the third commercial single-phase hydroelectric AC power plant in the United States to provide long-distance electricity.

It was completed on December 31, 1892, by Almarian William Decker to provide power to the city of Pomona, California, which was 14 miles away.

[36] In 1893, Decker designed the first American commercial three-phase power plant using alternating current—the hydroelectric Mill Creek No.

The original Niagara Falls Adams Power Plant with three two-phase generators was put into operation in August 1895, but was connected to the remote transmission system only in 1896.

Its generator (42 Hz, 240 kW) was made and installed by the Hungarian company Ganz, while the transmission line from the power plant to the City of Šibenik was 11.5 kilometers (7.1 mi) long, and the municipal distribution grid 3000 V/110 V included six transforming stations.

Notable contributors to the theoretical basis of alternating current calculations include Charles Steinmetz, Oliver Heaviside, and many others.

[38][39] Calculations in unbalanced three-phase systems were simplified by the symmetrical components methods discussed by Charles LeGeyt Fortescue in 1918.

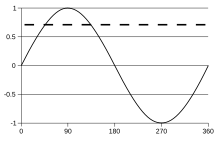

- Peak,

- Peak-to-peak amplitude,

- Effective value,

- Period

( US patent 373035 )