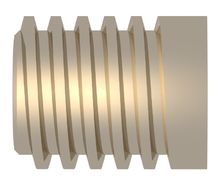

Trapezoidal thread form

It allows smoother engagement of the half nuts on a lathe leadscrew than a square thread.

This shape is easier to machine (faster cutting, longer tool life) than a square thread.

The tooth shape also has a wider base which means it is stronger (thus, the screw can carry a greater load) than a similarly sized square thread.

[8] The line of General Purpose (GP) Acme threads (ASME/ANSI B1.5-1997) are not designed to sustain external radial loads and both the nut and bolt are, ideally, independently supported (the nut by a linear guide and the screw by shaft bearings).

The drawback is that for a given amount of end play (axial clearance due solely to PD clearances), closer tolerances and a cleaner work environment are necessitated in the application of a Centralizing Acme thread.

Short-length threads are used on valve stems, hose connectors, bonnets on pressure cylinders, steering mechanisms, and camera lens movement.

The maximum diameter (within tolerance) at the crest of the external threads (called the max.

The minimum diameter (within tolerance) at the crest of the internal thread (called the min.