Alberta Taciuk process

[1][4][6] During that time, 1.5 million barrels (238.48×10^3 m3) of shale oil was extracted before the owner, Southern Pacific Petroleum Pty Ltd went into receivership.

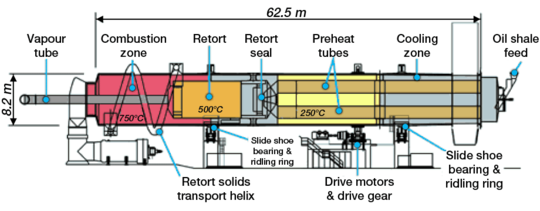

The distinguishing feature of the ATP is that the drying and pyrolysis of the oil shale or other feed, as well as the combustion, recycling, and cooling of spent materials and residues, all occur within a single rotating multi-chamber horizontal retort.

The resulting shale oil vapor is withdrawn from the retort through a vapour tube and recovered by condensation in other equipment.

[11] These advantages also apply to its oil sands applications, including increased oil yield, a simplified process flow, reduction of bitumen losses to tailings, elimination of the need for tailing ponds, improvement in energy efficiency compared with the hot water extraction process, and elimination of requirements for chemical and other additives.

[12] A complication of the ATP is that retorting operations can reach temperatures at which carbonate minerals within the shale decompose, increasing greenhouse gas emissions.

[2] As of 2008, ATP was used by the United States Environmental Protection Agency at a PCB-contaminated site near Buffalo, New York, and at the Waukegan Harbor, Illinois.