Anti-phase domain

An antiphase domain (APD) is a type of planar crystallographic defect in which the atoms within a region of a crystal are configured in the opposite order to those in the perfect lattice system.

For example, in an ordered AB alloy, if an A atom occupies the site usually occupied by a B atom, a type of crystallographic point defect called an antisite defect is formed.

If an entire region of the crystal is translated such that every atom in a region of the plane of atoms sits on its antisite, an antiphase domain is formed.

In other words, an APD is a region formed from antisite defects of a parent lattice.

[1] Crucially, crystals on either side of an antiphase boundary are related by a translation, rather than a reflection (a crystal twin) or an inversion (an inversion domain).

These planar defects are similar to stacking faults in that they are often created through slip of atomic planes and dislocation motion, but the degree of translation varies.

For anti-phase domains which only exhibit chemical disorder, the region is bounded by two complex stacking faults, which exhibit both stacking and chemical disorder.

[1] Thus, it takes 4 partial dislocations to fully restore the order of the crystal.

As the anti-phase boundary surface energy increases, the degree of separation between the partial dislocations will decrease to compensate.

The translation of the top layer can be broken down into two steps, indicated by the small arrows 1 and 2.

(b) The partial sliding of the top layer by the short vector 1 leads to the formation of a complex stacking fault.

(c) The complete sliding of the top layer with the translation magnitude given by a unit lattice translation (1+2), resulting in the formation of an anti-phase boundary.

If the top plane slips by two complete lattice spacings (1, 2, 3, and 4), a superdislocation is formed, and this is required for the perfect crystal structure to be restored.

It is expected that this superdislocation, consisting of two perfect lattice translations, dissociates into four different partial dislocations with two on each side.

[2] Figure 2: An antiphase boundary created by four partial dislocations (1,2,3,4), surrounded by complex stacking faults.

[1] Order strengthening brought about from the interaction of dislocations with ordered precipitates, forming anti-phase boundaries as dislocations move throughout the crystal, can lead to significant increases in strength and creep resistance.

For this reason, order strengthening is often exploited for high-temperature creep resistant superalloys used in turbine blades.

[2] Antiphase domains carry with them a surface energy penalty when compared to the perfect lattice due to their chemical disorder, and the presence of these boundaries impedes dislocation motion throughout the crystal, leading to increased strength under shear stress.

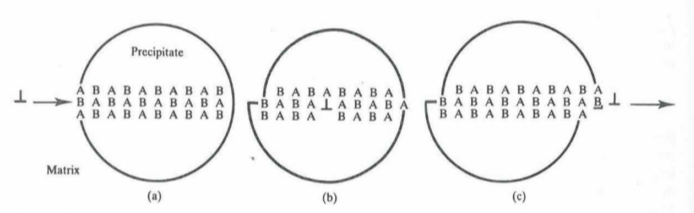

Figure 3 below shows the process of an edge dislocation propagating through an ordered particle.

As the dislocation moves throughout the particle, lattice planes are displaced from their equilibrium configuration, and A-A bonds and B-B bonds are formed throughout the slip plane.

This can increase the degree of strengthening created from precipitation hardening, making it more difficult for cutting to occur, and instead increasing the likelihood of Orowan bowing around the precipitate.

Figure 3: The process of an edge dislocation moving through an ordered precipitate.

In (c), the dislocation exits the precipitate, leading to an increase in surface energy from increased surface area and a higher-energy bonding configuration.

The degree of order strengthening depends on both this ratio and whether the alloy is in the early or late stages of precipitation.

During the early stages of precipitation, the increase in shear stress can be expressed as:

(Similar defects form in GaN on silicon, where they are correctly identified as inversion domains).

In the figure, GaAs is grown on a misoriented surface of Si (details are not discussed here).

The misorientation causes the Ga and As atoms in region B to be on opposite sites compared to the crystal matrix.

In mixed oxidation state materials like magnetite, antiphase domains and antiphase domain boundaries can occur as a result of charge-ordering even though there are no changes in atom locations.

[4] An antiphase domain boundary can form if two subsurface FeII pairs meet when two terraces grow together.