Anti-roll bar

The first stabilizer bar patent was awarded to Canadian inventor Stephen Coleman of Fredericton, New Brunswick on April 22, 1919.

[1][2] Anti-roll bars were unusual on pre-WW2 cars due to the generally much stiffer suspension and acceptance of body roll.

An anti-sway or anti-roll bar is intended to reduce the lateral tilt (roll) of the vehicle on curves, sharp corners, or large bumps.

Although there are many variations in design, the object is to induce a vehicle's body to remain as level as possible by forcing the opposite wheel's shock absorber, spring, or suspension rod in the same direction as the one being impacted.

The anti-roll bar forces the opposite (inner) wheel's suspension to compress as well, thereby keeping the body in a more level lateral attitude.

When both front and rear anti-roll bars are fitted, their combined effect can help maintain a vehicle's tendency to roll towards the general slope of the terrain.

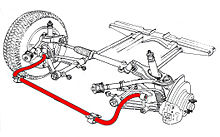

It is usually constructed out of a cylindrical steel bar, formed into a "U" shape, that connects to the body at two points along its longer center section, and on each end.

The link is connected in turn to a spot near a wheel or axle, transferring forces from the heavily loaded side of a suspension to the opposite.

One effect of body lean, for typical unibody suspension geometry, is positive camber of the wheels on the outside of the turn and negative on the inside, which reduces their cornering grip (especially with cross ply tires).

Increasing this stiffness does not change the steady state total load (weight) transfer from the inside wheels to the outside, it only reduces body lean.

Excessive roll stiffness, typically achieved by configuring an anti-roll bar too aggressively, can make the inside wheels lift off the ground during hard cornering.

However many later "MacPherson strut" suspensions have reverted to using wishbones rather than the simplified track control arm of the original design.

[6] The anti-roll bar could be stiffened by the suspension ECU during hard cornering, minimizing body roll to 2 degrees.

T=Vehicle track width (inches)

K=Fractional lever arm ratio (movement at roll bar / movement at wheel)

d=Bar diameter (inches)

R=Effective arm length (inches)

L=Half length of bar (inches)

S=Length of lever arm (inches)

Q=Stiffness (lb*in per degree) [ 3 ]