SM-65 Atlas

It was built for the U.S. Air Force by the Convair Division of General Dynamics at an assembly plant located in Kearny Mesa, San Diego.

The initial versions were stored at ground level and thus subject to attack by Soviet bombers, which greatly reduced their suitability for this role.

Today ULA supports the larger Atlas V, which combines the Centaur upper stage with a new booster.

As such, its early development was quite chaotic, with plans changing rapidly as flight tests revealed issues.

Atlas began in 1946 with the award of an Army Air Forces research contract to Convair for the study of a 1,500-to-5,000-mile (2,400 to 8,000 km) range missile that might at some future date carry a nuclear warhead.

[3]: 70 At the time, the smallest atomic warheads were all larger than the maximum theoretical payloads of the planned long range missiles, so the contract was canceled in 1947, but the Army Air Forces allowed Convair to launch the three almost-completed research vehicles using the remaining contract funds.

The three flights were only partially successful, but did show that balloon tanks and gimbaled rocket engines were valid concepts.

Project Atlas was assigned the highest Air Force development priority on 14 May 1954 by General Thomas D.

[3]: 106 A major development and test contract was awarded to Convair on 14 January 1955 for a 10-foot (3 m) diameter missile to weigh about 250,000 lb (113,400 kg).

The first successful flight of a highly instrumented Atlas missile to full range occurred 28 November 1958.

[7] By 1965, with the second-generation Titan II having reached operational status, the Atlas was obsolete as a missile system and had been phased out of military use.

[8] The Atlas's complicated, unconventional design proved difficult to debug compared with rocket families such as Thor and Titan which used conventional aircraft-style structures and two stage setups and there were dozens of failed launches during the early years.

After watching Atlas Serial 7D explode shortly after its nighttime launch, Mercury astronaut Gus Grissom remarked "Are we really going to get on top of one of those things?

Atlas was unusual in its use of balloon tanks for the propellants, made of very thin stainless steel with minimal or no rigid support structures, as already pioneered by the Soviet R-5 first launched in 1953.

The booster section would then be released by a series of hydraulic clamps (aside from the early test model Atlas B, which used explosive bolts) and slide off the missile on two tracks.

Booster staging took place at roughly two minutes into launch, although the exact timing could vary considerably depending on the model of Atlas as well as the particular mission being flown.

However, technology advanced quickly and not long after design work on Atlas was completed, Convair rival Martin proposed a solution to the air-starting problem.

Later space launcher variants of the Atlas used the MA-5 propulsion system with twin turbopumps on each booster engine, driven by a common gas generator.

Total sea level thrust for these three-engine Atlas Es and Fs was 389,000 lbf (1,730 kN).

Mk 2 "heat sink" re-entry vehicle (RV)[17] with a W49 thermonuclear weapon, combined weight 3,700 lb (1,680 kg) and yield of 1.44 megatons (Mt).

Like the Atlas, the use of cryogenic liquid oxygen meant that the missile could not be kept in the state of flight readiness indefinitely and was largely useless for its intended purpose (military) and was similarly developed into a space launch vehicle, initially delivering Sputnik and Vostok into orbit.

[21] It was a test model designed to verify the structure and propulsion system, and had no sustainer engine or separable stages.

[21] The Convair X-12/SM-65B was the second prototype version, introducing the stage and a half system that was a hallmark of the Atlas rocket program.

This version was the first American rocket to achieve a flight distance that could be considered intercontinental when it flew 6,325 miles (10,180 km).

This very low dry weight gave Atlas D a range of up to 9,000 miles (14,500 km), or to orbit payloads without requiring an upper stage.

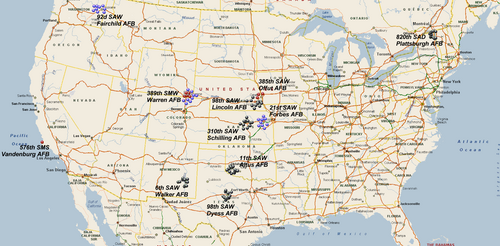

[34] The SM-65E Atlas were based in horizontal "semi-hard" or "coffin" facilities that protected the missile against over-pressures up to 25 psi (170 kPa).

In this arrangement the missile, its support facilities, and the launch operations building were housed in reinforced concrete structures that were buried underground; only the roofs protruded above ground level.

Built of heavily reinforced concrete, the huge silos were designed to protect the missiles from over-pressures of up to 100 psi (690 kPa).

Four sites and their missiles were destroyed during propellant loading exercises (known as PLXs) when liquid oxygen leaked and fires ensued.

Related lists This article incorporates public domain material from the Air Force Historical Research Agency 50. https://www.nytimes.com/1964/03/10/archives/atlas-blows-up-in-its-site-at-new-mexico-desert-base.html