Balloon tank

Constructed of very thin 301 extra-full-hard stainless steel 0.014–0.037 inch (0.3556–0.9398 mm) thick,[1] prior to integration into the Atlas or Centaur rocket body the tanks are inflated with nitrogen to give them their shape and strength.

However, the airframes could be handled without tank pressurization through the use of a "stretch" mechanism (which basically helped support vehicle weight and prevented collapse).

This tank technology made feasible a relatively simple stage-and-a-half design for Atlas instead of the more complicated staging used in later LGM-25 Titan ICBMs.

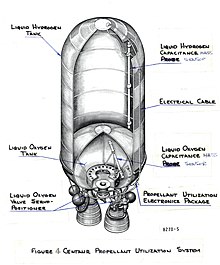

After its initial development in the Atlas rocket, Bossart used the same technology with the high-energy Centaur upper stage.

A 2009 article mentions a review of hardware serial numbers which lead to the conclusion that the satellite payload had not yet been mounted on the rocket during the failed test.