Trickling filter

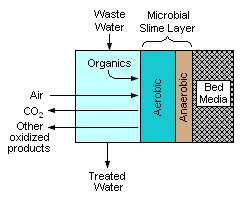

It consists of a fixed bed of some material, such as rocks, coke, gravel, slag, polyurethane foam, sphagnum peat moss, ceramic, or plastic media, over which sewage or other wastewater flows downward and causes a layer of microbial slime (biofilm) to grow, covering the bed of media.

Aerobic conditions are maintained by splashing, diffusion, and either by forced-air flowing through the bed or natural convection of air if the filter medium is porous.

The removal of pollutants from the waste water stream involves both absorption and adsorption of organic compounds and some inorganic species (such as nitrite and nitrate ions) by the layer of microbial biofilm.

As the biofilm layer thickens, it eventually sloughs off into the liquid flow and subsequently forms part of the secondary sludge.

Filters utilizing higher-density media, such as sand, foam and peat moss do not produce a sludge that must be removed, but may require forced air blowers, backwashing, and/or an enclosed anaerobic environment.

[citation needed] The biofilm that develops in a trickling filter may become several millimetres thick and is typically a gelatinous matrix that may contain many species of bacteria, ciliates and amoeboid protozoa, annelids, round worms, insect larvae, other microfauna.

[1] Settled sewage is delivered to a reservoir at the centre of the spindle via some form of dosing mechanism, often a tipping bucket device on small filters.

Multi-pass systems result in higher treatment quality and assist in removing Total Nitrogen (TN) levels by promoting nitrification in the aerobic media bed and denitrification in the anaerobic septic tank.

Types of media most commonly used include coke, pumice, plastic matrix material, open-cell polyurethane foam, clinker, gravel, sand and geotextiles.

[2] The treatment of industrial wastewater may involve specialized trickling filters which use plastic media and high flow rates.