Buddle pit

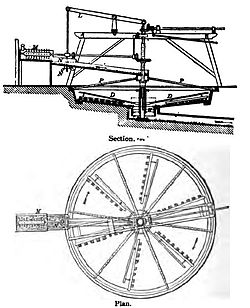

The fixed and revolving cast-iron heads, shafting, bevel wheels, and driving pulleys, are usually procured from a firm of machinery makers.

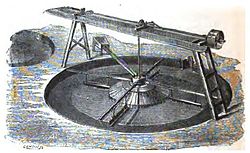

The sides of the buddle pit are formed of stone or brick, set in mortar, and the floor, which has an inclination outwards of 1 in 30, is made either of smooth planed boards or cement run upon a layer of concrete.

To each of the four arms a board is attached, carrying a cloth or a series of brushes, which sweep round and smooth out each successive layer of mineral as soon as it is formed.

The outflow of the waste waters takes place through the small sluice gate shown in the circumference of the huddle.

At this point the machine is stopped, a groove is cut from the cone to the circumference, and samples of the ore are taken and washed on a vanning shovel.

The middles are likewise re-treated, the ores of approximately the same percentage being treated in the same machine until all the mineral is abstracted, and the waste contains not more than ½ per cent.

The mineral must be handled several times, always a costly proceeding, and the machine must be stopped when full, and lie idle until emptied.