CANDU reactor

CANDU reactors were first developed in the late 1950s and 1960s by a partnership between Atomic Energy of Canada Limited (AECL), the Hydro-Electric Power Commission of Ontario, Canadian General Electric, and other companies.

Candu Energy offers support services for existing sites and is completing formerly stalled installations in Romania and Argentina through a partnership with China National Nuclear Corporation.

SNC Lavalin, the successor to AECL, is pursuing new CANDU 6 reactor sales in Argentina (Atucha 3), as well as China and Britain[citation needed].

In 2017, a consultation with industry led Natural Resources Canada to establish a "SMR Roadmap"[2] targeting the development of small modular reactors (SMRs).

Newer CANDU plants, such as the Darlington Nuclear Generating Station near Toronto, Ontario, use a diffuser to spread the warm outlet water over a larger volume and limit the effects on the environment.

This issue was so major that even the relatively small pressure vessel originally intended for use in the NPD prior to its mid-construction redesign could not be fabricated domestically and had to be manufactured in Scotland instead.

A significant operational advantage of online refuelling is that a failed or leaking fuel bundle can be removed from the core once it has been located, thus reducing the radiation levels in the primary cooling loop.

Thus if the chain reaction accelerates in one section of the reactor, the change will propagate itself only slowly to the rest of the core, giving time to respond in an emergency.

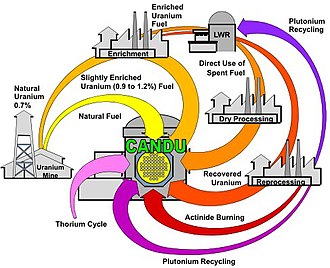

Canada developed the heavy-water-moderated design in the post–World War II era to explore nuclear energy while lacking access to enrichment facilities.

War-era enrichment systems were extremely expensive to build and operate, whereas the heavy water solution allowed the use of natural uranium in the experimental ZEEP reactor.

The CANDU designs have several emergency cooling systems, as well as having limited self-pumping capability through thermal means (the steam generator is well above the reactor).

Because these rods are inserted into the low-pressure calandria, not the high-pressure fuel tubes, they would not be "ejected" by steam, a design issue for many pressurized-water reactors.

[18] For instance, imposed construction delays led to roughly a doubling of the cost of the Darlington Nuclear Generating Station near Toronto, Ontario.

[19] In 2002 two CANDU 6 reactors at Qinshan in China were completed on-schedule and on-budget, an achievement attributed to tight control over scope and schedule.

The plan, by law, involved sales to non-military applications only, but some speculated that the exports could have freed American tritium for the United States nuclear weapons program.

[25]: 10 Consequently, the Canadian Nuclear Laboratories in 2024 announced a decades-long program to refurbish existing CANDU plants and equip them with tritium breeding facilities.

Janes Intelligence Review quotes the Chairman of the Indian Atomic Energy Commission as admitting to the tritium extraction plant, but refusing to comment on its use.

[37][38] The second CANDU was the Douglas Point reactor, a more powerful version rated at roughly 200 MWe and located near Kincardine, Ontario.

WR-1, located at the AECL's Whiteshell Laboratories in Pinawa, Manitoba, used vertical pressure tubes and organic oil as the primary coolant.

This improvement at larger sizes is offset by the sudden appearance of large quantities of power on the grid, which leads to a lowering of electricity prices through supply and demand effects.

Predictions in the late 1960s suggested that growth in electricity demand would overwhelm these downward pricing pressures, leading most designers to introduce plants in the 1000 MWe range.

Two new CANDU reactors have been proposed for Darlington with Canadian government help with financing,[49] but these plans ended in 2009 due to high costs.

Interest has been expressed in Western Canada, where CANDU reactors are being considered as heat and electricity sources for the energy-intensive oil sands extraction process, which currently uses natural gas.

In addition, the pace of construction in the United States had meant that cost overruns and delayed completion was generally over, and subsequent reactors would be cheaper.

The CANDU was deliberately designed to reduce the need for very large machined parts, making it suitable for construction by countries without a major industrial base.

[62] Construction of the RAPP-2 reactor was still underway when India detonated its first atomic bomb in 1974, leading to Canada ending nuclear dealings with the country.

In 1972, AECL submitted a design based on the Pickering plant to Argentina's Comision Nacional de Energia Atomica process, in partnership with the Italian company Italimpianti.

[64] There have been ongoing negotiations to open more CANDU 6 reactors in the country, including a 2007 deal between Canada, China and Argentina, but to date no firm plans have been announced.

[citation needed] In the 1980s, the pressure tubes in the Pickering A reactors were replaced ahead of design life due to unexpected deterioration caused by hydrogen embrittlement.

In order to make the successor companies more attractive for private investors, $19.4 billion in "stranded debt" was placed in the control of the Ontario Electricity Financial Corporation.

- Fuel bundle

- Calandria (reactor core)

- Adjuster rods

- Pressurizer

- Steam generator

- Light-water pump

- Heavy-water pump

- Fueling machines

- Heavy-water moderator

- Pressure tube

- Steam going to steam turbine

- Cold water returning from turbine

- Containment building made of reinforced concrete