Optical disc drive

), relatively small volumes of data (e.g. a standard DVD holds 4.7 gigabytes, however, higher-capacity formats such as multi-layer Blu-ray Discs exist) for local use, and data for distribution, but only on a small scale; mass-producing large numbers of identical discs by pressing (replication) is cheaper and faster than individual recording (duplication).

The second servo moves the pickup head along the disc's radius, keeping the beam on the track, a continuous spiral data path.

[13] Some CD players have automatic gain control (AGC) to vary the power of the laser to ensure reliable playback of CD-RW discs.

[16] On factory-pressed read only media (ROM), during the manufacturing process the tracks are formed by pressing a thermoplastic resin into a nickel stamper that was made by plating a glass 'master' with raised 'bumps' on a flat surface, thus creating pits and lands in the plastic disk.

[citation needed] This changes the reflectivity of the dye, thereby creating marks that can be read like the pits and lands on pressed discs.

For rewritable CD-RW, DVD-RW, DVD+RW, DVD-RAM, or BD-RE media, the laser is used to melt a crystalline metal alloy in the recording layer of the disc.

[19][20] Some drives support Hewlett-Packard's LightScribe, or the alternative LabelFlash photothermal printing technology for labeling specially coated discs.

But switching to CAV requires considerable changes in hardware design, so instead most drives use the zoned constant linear velocity (Z-CLV) scheme.

A Z-CLV recorder rated at "52×", for example, would write at 20× on the innermost zone and then progressively increase the speed in several discrete steps up to 52× at the outer rim.

In actuality, a CD speed of "52×" are approximately 10,000 rpm (see table, different for DVD and Blu-ray), given that drives are advertised with their angular velocities.

[37][38] Current optical drives use either a tray-loading mechanism, where the disc is loaded onto a motorized tray (as utilized by half-height, "desktop" drives), a manually operated tray (as utilized in laptop computers, also called slim type), or a slot-loading mechanism, where the disc is slid into a slot and drawn in by motorized rollers.

Unlike tray and slot loading mechanisms by default, top-load optical drives can be opened without being connected to power.

Some early CD-ROM drives used a mechanism where CDs had to be inserted into special cartridges or caddies, somewhat similar in appearance to a 3.5 inch micro floppy diskette.

Some early optical drives have dedicated buttons for CD playback controls on their front panel, allowing them to act as a standalone compact disc player.

Early consumer grade laptops simply had no built-in high-speed interface for supporting an external storage device.

A higher value may increase the chance of successfully reading individual damaged sectors, but at the expense of responsiveness, since it adds delays during which the device seems unresponsive to the computer.

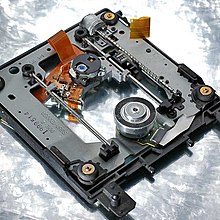

Two parallel guide rods that run between upper left and lower right in the photo carry the "sled", the moving optical read-write head.

The motor, itself, is the short gray cylinder just to the left of the most-distant shock mount; its shaft is parallel to the support rods.

In contrast, the mechanism shown in the second photo, which comes from a cheaply made DVD player, uses less accurate and less efficient brushed DC motors to both move the sled and spin the disc.

Some older drives use a DC motor to move the sled, but also have a magnetic rotary encoder to keep track of the position.

[56] The first erasable optical disc drives were announced in 1983, by Matsushita (Panasonic),[57] Sony, and Kokusai Denshin Denwa (KDDI).

[59] In September 1992, Sony announced the MiniDisc format, which was supposed to combine the audio clarity of CD's and the convenience of a cassette size.

[61] Sales of DVD-ROM drives for computers in the U.S. began on March 24, 1997, when Creative Labs released their PC-DVD kit to the market.

In response, manufacturers of CD recorders began shipping drives with "buffer underrun protection" (under various trade names, such as Sanyo's "BURN-Proof", Ricoh's "JustLink" and Yamaha's "Lossless Link").

These can suspend and resume the recording process in such a way that the gap the stoppage produces can be dealt with by the error-correcting logic built into CD players and CD-ROM drives.

[72][73][74] While drives are burning DVD+R, DVD+RW and all Blu-ray formats, they do not require any such error correcting recovery as the recorder is able to place the new data exactly on the end of the suspended write effectively producing a continuous track (this is what the DVD+ technology achieved).

These resemble the block-writable access offered by magnetic media closely enough that many conventional file systems will work as-is.

Although generous gaps (the padding referred to above) are left between blocks, the drive nevertheless can occasionally miss and either destroy some existing data or even render the disc unreadable.

Quoting Philips, the RID "enables a trace for each disc back to the exact machine on which it was made using coded information in the recording itself.

[76] A significant motivation for introducing the SID code was to identify disc manufacturing plants producing unauthorised copies of commercial CDs.