Capillary pressure

Capillary pressure can serve as both an opposing or driving force for fluid transport and is a significant property for research and industrial purposes (namely microfluidic design and oil extraction from porous rock).

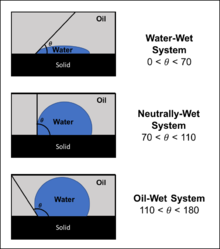

These forces can be described by the interfacial tension and contact angle of the fluids, and the radius of the capillary tube.

For instance, as the capillary pressure increases, a wettable surface in a channel will pull the liquid through the conduit.

In the field of diagnostics, the lateral flow test is a common microfluidic device platform that utilizes capillary forces to drive fluid transport through a porous membrane.

An advantage to this design, and several other microfluidic devices, is its simplicity (for example, its lack of human intervention during operation) and low cost.

[5] Another example of point-of-care work involving a capillary pressure-related design component is the separation of plasma from whole blood by filtration through porous membrane.

Efficient and high-volume separation of plasma from whole blood is often necessary for infectious disease diagnostics, like the HIV viral load test.

An example of this point-of-care filtration device is a packed-bed filter, which has demonstrated the ability to separate plasma and whole blood by utilizing asymmetric capillary forces within the membrane pores.

[6] Capillary pressure plays a vital role in extracting sub-surface hydrocarbons (such as petroleum or natural gas) from underneath porous reservoir rocks.

[7] Additionally, capillary pressure in porous rocks has been shown to affect phase behavior of the reservoir fluids, thus influencing extraction methods and recovery.

[8] It is crucial to understand these geological properties of the reservoir for its development, production, and management (e.g. how easy it is to extract the hydrocarbons).

[dubious – discuss]The Deepwater Horizon oil spill is an example of why capillary pressure is significant to the petrochemical industry.

Although capillary pressure studies (or potentially a lack thereof) do not necessarily sit at the root of this particular oil spill, capillary pressure measurements yield crucial information for understanding reservoir properties that could have influenced the engineering decisions made in the Deepwater Horizon event.

[10] For reference, capillary pressures between air and brine (which is a significant system in the petrochemical industry) have been shown to range between 0.67 and 9.5 MPa.

[11] There are various ways to predict, measure, or calculate capillary pressure relationships in the oil and gas industry.

Meanwhile, the volume of mercury at each given pressure is recorded and given as a pore size distribution, or converted to relevant oil/gas data.

However, the entire process of injecting mercury and collecting data occurs rapidly in comparison to other methods.

[7] The Porous Plate Method is an accurate way to understand capillary pressure relationships in fluid-air systems.

The rotation speed is correlated to capillary pressure by the following equation: where: The primary benefits to this method are that it's rapid (producing curves in a matter of hours) and is not restricted to being performed at certain temperatures.

The first major contributions to the study of needle ice, or simply, frost heaving were made by Stephen Taber (1929) and Gunnar Beskow (1935), who independently aimed to understand soil freezing.

Taber’s initial work was related to understanding how the size of pores within the ground influenced the amount of frost heave.

He also discovered that frost heave is favorable for crystal growth and that a gradient of soil moisture tension drives water upward toward the freezing front near the top of the ground.

Thus, with additional heat loss, it is most favorable for water to travel up the capillary and freeze in the top cylinder (as needle ice continues to grow atop itself above the soil surface).

[21] Due to limitations in technology and bodily structure, most studies of capillary activity are done in the retina, lip and skin, historically through cannulation or a servo-nulling system.