Cellulose acetate

[1][verification needed] A bioplastic, cellulose acetate is used as a film base in photography, as a component in some coatings, and as a frame material for eyeglasses;[2] it is also used as a synthetic fiber in the manufacture of cigarette filters and playing cards.

The German chemists Arthur Eichengrün and Theodore Becker invented the first soluble forms of cellulose acetate in 1903.

[3] In 1904, Camille Dreyfus and his younger brother Henri performed chemical research and development on cellulose acetate in a shed in their father's garden in Basel, Switzerland, which was then a center of the dye industry.

[4] In 1913, after some twenty thousand separate experiments, they produced excellent laboratory samples of continuous filament yarn, something that had eluded the cellulose acetate industry to this time.

The first yarn was of fair quality, but sales resistance was heavy, and silk associates worked zealously to discredit acetate and discourage its use.

However, the thermoplastic nature of acetate made it an excellent fiber for moiré because the pattern was permanent and did not wash away.

The same characteristic also made permanent pleating a commercial fact for the first time, and gave great style impetus to the whole dress industry.

to give fabrics excellent wrinkle recovery, good heft, handle, draping quality, quick drying, proper dimensional stability, cross-dye pattern potential, at a very competitive price.

[9] Acetate is a low cost, manufactured fiber, which has good draping qualities[attribution needed].

Since the 1980s, polyester film stock (sometimes referred to under Kodak's trade name "ESTAR Base") has become more commonplace, particularly for archival applications.

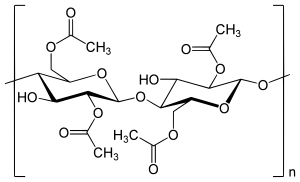

It is subjected to a controlled, partial hydrolysis to remove the sulfate and a sufficient number of acetate groups to give the product the desired properties.

The anhydroglucose unit is the fundamental repeating structure of cellulose and has three hydroxyl groups which can react to form acetate esters.

As the filaments emerge, the solvent is evaporated in warm air via dry spinning, producing fine cellulose acetate fibers.

The mixture is aged 20 hours during which partial hydrolysis occurs and acid resin precipitates as flakes.

[20][21] Cellulose acetate is marketed under various trade names, such as Tenite (Eastman Chemical Company), zyl and zylonite,[2] Cellon (Deutsche Celluloid Fabrik in Eilenburg, Germany),[22] and Rhodoid (Soc.

[22] Cast film of cellulose acetate manufactured by Celanese (Derbyshire, UK) is sold as Clarifoil.

Schützenberger, P. "Action de l'acide acétique anhydre sur la cellulose, l'amidon, les sucres, la mannite et ses congénères, les glucosides et certaines matières colorantes végétales."