Cellulose fiber

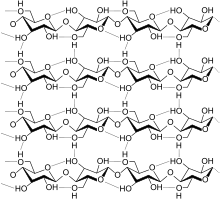

Cellulose was discovered in 1838 by the French chemist Anselme Payen, who isolated it from plant matter and determined its chemical formula.

A result of these differences in structure is that, compared to starch and other carbohydrates, cellulose cannot be broken down into its glucose subunits by any enzymes produced by animals.

Since cellulose does not have a helical structure like amylose, it does not bind to iodine to form a colored product.

Fibers may also be produced from Laminaria hyperborea nozzle-pressurized gyration and wet spinning, along with resonant acoustic mixing[5].

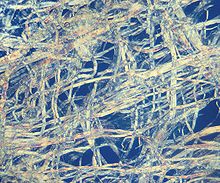

Because the natural fibers make hydrogen bonds between the long chains, they have the necessary stiffness and strength.

The major constituents of natural fibers (lignocelluloses) are cellulose, hemicellulose, lignin, pectin and ash.

Hydrophilicity, roughness and surface charge determine the interaction of cellulose fibers with an aqueous environment.

[7] Due to the high swelling propensity of lignocellulosic fibers, a correlation between the zeta potential and the water uptake capability has been observed.

Rayon and acetate are both artificial fibers, but not fully synthetic, being a product of a chemically digested feedstock comprising natural wood.

Although these artificial fibers were discovered in the mid-nineteenth century, successful modern manufacture began much later.

[citation needed] As ashless and non-abrasive filtration, make cleanup effortless after the filtering process without damage in pumps or valves.

[12] Although the process is not as environmentally friendly as "bamboo fiber" appears, planting & harvesting bamboo for fiber can, in certain cases, be more sustainable and environmentally friendly than harvesting slower growing trees and clearing existing forest habitats for timber plantations.