Cleave (fiber)

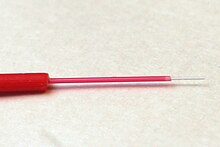

A cleave in an optical fiber is a deliberate, controlled break, intended to create a perfectly flat end face perpendicular to the fiber's longitudinal axis.

[1][2] A good cleave is required for a successful low loss splice of an optical fiber, often it is the case that fibers spliced by identical methods tend to have different losses, this difference can often be attributed to the quality of their initial cleaves.

This process involves the introduction of a crack in the fiber, generally utilizing a cutting tool made from a material such as diamond, sapphire, or tungsten carbide, followed by the application of tensile stress in the vicinity of the crack.

[5] Certain implementations may apply the tensile force uniformly across the cross-section of the fiber, whereas others might bend the fiber around a curved surface, causing excessive tensile stress on the outside of the bend.

[4] The introduction of the crack in the fiber may also be generated in different ways; the crack may be introduced at a single point on the circumference or it may be generated all along the circumference of the fiber before the application of the tensile force.