Coal combustion products

In modern coal-fired power plants, fly ash is generally captured by electrostatic precipitators or other particle filtration equipment before the flue gases reach the chimneys.

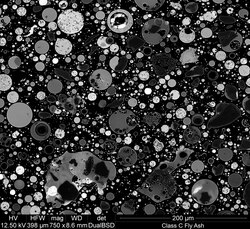

This makes it necessary that, if fly ash is used in an optimal way to replace cement in concrete production, it must be processed using beneficiation methods like mechanical air classification.

For this reason, much of the current debate around fly ash disposal revolves around creating specially lined landfills that prevent the chemical compounds from being leached into the ground water and local ecosystems.

[24] Coal ash uses include (approximately in order of decreasing importance): Other applications include cosmetics, toothpaste, kitchen counter tops,[28] floor and ceiling tiles, bowling balls, flotation devices, stucco, utensils, tool handles, picture frames, auto bodies and boat hulls, cellular concrete, geopolymers, roof tiles, roofing granules, decking, fireplace mantles, cinder block, PVC pipe, structural insulated panels, house siding and trim, running tracks, blasting grit, recycled plastic lumber, utility poles and crossarms, railway sleepers, highway noise barriers, marine pilings, doors, window frames, scaffolding, sign posts, crypts, columns, railroad ties, vinyl flooring, paving stones, shower stalls, garage doors, park benches, landscape timbers, planters, pallet blocks, molding, mail boxes, artificial reef, binding agent, paints and undercoatings, metal castings, and filler in wood and plastic products.

Engineering properties that affect the use of fly ash in embankments include grain size distribution, compaction characteristics, shear strength, compressibility, permeability, and frost susceptibility.

This allows for the establishment of design criteria, and determination of the proper chemical additive and admixture rate that achieves the desired engineering properties.

Equipment for the stabilization and modification processes include: chemical additive spreaders, soil mixers (reclaimers), portable pneumatic storage containers, water trucks, deep lift compactors, motor graders.

Leading manufacturers use an industrial standard known as "Pulverized fuel ash for lime-Pozzolana mixture" using over 75% post-industrial recycled waste, and a compression process.

[46][47] Fly ash, when treated with sodium hydroxide, appears to function well as a catalyst for converting polyethylene into substance similar to crude oil in a high-temperature process called pyrolysis[48] and utilized in waste water treatment.

[63][64] In 2014, residents living near the Buck Steam Station in Dukeville, North Carolina, were told that "coal ash pits near their homes could be leaching dangerous materials into groundwater".

Of the state's 24 coal ash dumpsites with available data, 22 have released toxic pollutants including arsenic, cobalt, and lithium, into groundwater, rivers and lakes.

[67] Tennessee In 2008, the Kingston Fossil Plant in Roane County spilled 1.1 billion gallons of coal ash into the Emory and Clinch Rivers and damaged nearby residential areas.

It is the largest industrial spill in the U.S.[68] Groundwater surrounding every single one of the 16 coal-burning power plants in Texas has been polluted by coal ash, according to a study by the Environmental Integrity Project (EIP).

At 10 of the sites, lithium, which causes neurological disease, was found in the groundwater at concentrations more than 1,000 micrograms per liter, which is 25 times the maximum acceptable level.

Trace elements, such as, iron, manganese, zinc, copper, lead, nickel, chromium, cobalt, arsenic, cadmium, and mercury, can be found at higher concentrations compared to bottom ash and the parent coal.

[72] Once exposed to fly ash contaminating the water, aquatic organisms have had increased levels of calcium, zinc, bromine, gold, cerium, chromium, selenium, cadmium, and mercury.

[73] In the UK, fly ash lagoons from old coal-fired power stations have been made into nature reserves such as Newport Wetlands,[74][75] providing habitat for rare birds and other wildlife.

The resulting impoundments (ash ponds) are typically large and stable for long periods, but any breach of their dams or bunding is rapid and on a massive scale.

[78] In 2014, 39,000 tons of ash and 27 million gallons (100,000 cubic meters) of contaminated water spilled into the Dan River near Eden, NC from a closed North Carolina coal-fired power plant that is owned by Duke Energy.

The agency continued to classify coal ash as non-hazardous (thereby avoiding strict permitting requirements under Subtitle C of the Resource Conservation and Recovery Act (RCRA), but with new restrictions: The regulation was designed to prevent pond failures and protect groundwater.

Potentially toxic trace elements in coal include arsenic, beryllium, cadmium, barium, chromium, copper, lead, mercury, molybdenum, nickel, radium, selenium, thorium, uranium, vanadium, and zinc.

[93] Lime (CaO) reacts with water (H2O) to form calcium hydroxide [Ca(OH)2], giving fly ash a pH somewhere between 10 and 12, a medium to strong base.

[94] These include wearing protective goggles, respirators and disposable clothing and avoiding agitating the fly ash in order to minimize the amount which becomes airborne.

The National Academy of Sciences noted in 2007 that "the presence of high contaminant levels in many CCR (coal combustion residue) leachates may create human health and ecological concerns".

[95] In response to the court remand, EPA published its "CCR Part A" final rule on August 28, 2020, requiring all unlined ash ponds to retrofit with liners or close by April 11, 2021.

[96][97][98] EPA published its "CCR Part B" rule on November 12, 2020, which allows certain facilities to use an alternative liner, based on a demonstration that human health and the environment will not be affected.

[99] In October 2020 EPA published a final effluent guidelines rule that reverses some provisions of its 2015 regulation, which had tightened requirements on toxic metals in wastewater discharged from ash ponds and other power plant wastestreams.

[103] The Ministry of Environment, Forest and Climate Change of India first published a gazette notification in 1999 specifying use of fly ash and mandating a target date for all thermal power plants to comply by ensuring 100% utilisation.

With housing sector consuming 67% of the cement, there is a huge scope for incorporating fly ash in both the increasing share of PPC and low to moderate strength concrete.

Similar misconceptions exists in countries like US[107] but evidence to the contrary is the use of HVFA in many large projects where design mixes have been used under strict quality control.