Computer-integrated manufacturing

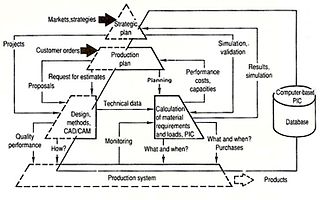

Typically CIM relies on closed-loop control processes based on real-time input from sensors.

CIM implies that there are at least two computers exchanging information, e.g. the controller of an arm robot and a micro-controller.

CIM is most useful where a high level of ICT is used in the company or facility, such as CAD/CAM systems, and the availability of process planning and its data.

Some or all of the following subsystems may be found in a CIM operation: Computer-aided techniques: Devices and equipment required: Technologies: Others: CIMOSA (Computer Integrated Manufacturing Open System Architecture), is a 1990s European proposal for an open systems architecture for CIM developed by the AMICE Consortium as a series of ESPRIT projects.

[8][9] The goal of CIMOSA was "to help companies to manage change and integrate their facilities and operations to face world wide competition.