Corrosion

As a result, methods to reduce the activity of the exposed surface, such as passivation and chromate conversion, can increase a material's corrosion resistance.

In any given environment (one standard medium is aerated, room-temperature seawater), one metal will be either more noble or more active than others, based on how strongly its ions are bound to the surface.

An extreme example is graphite, which releases large amounts of energy upon oxidation, but has such slow kinetics that it is effectively immune to electrochemical corrosion under normal conditions.

Passivation in natural environments such as air, water and soil at moderate pH is seen in such materials as aluminium, stainless steel, titanium, and silicon.

On the other hand, unusual conditions may result in passivation of materials that are normally unprotected, as the alkaline environment of concrete does for steel rebar.

In the worst case, almost all of the surface will remain protected, but tiny local fluctuations will degrade the oxide film in a few critical points.

Stainless steel can pose special corrosion challenges, since its passivating behavior relies on the presence of a major alloying component (chromium, at least 11.5%).

This chemical reaction robs the material of chromium in the zone near the grain boundary, making those areas much less resistant to corrosion.

For example, materials used in aerospace, power generation, and even in car engines must resist sustained periods at high temperature, during which they may be exposed to an atmosphere containing the potentially highly-corrosive products of combustion.

The formation of oxides on stainless steels, for example, can provide a protective layer preventing further atmospheric attack, allowing for a material to be used for sustained periods at both room and high temperatures in hostile conditions.

Accelerated low-water corrosion (ALWC) is a particularly aggressive form of MIC that affects steel piles in seawater near the low water tide mark.

The suspected mechanism is firstly the deposition of a graphite layer on the surface of the metal, usually from carbon monoxide (CO) in the vapor phase.

Various treatments are used to slow corrosion damage to metallic objects which are exposed to the weather, salt water, acids, or other hostile environments.

Some unprotected metallic alloys are extremely vulnerable to corrosion, such as those used in neodymium magnets, which can spall or crumble into powder even in dry, temperature-stable indoor environments unless properly treated.

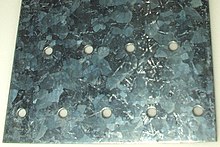

When surface treatments are used to reduce corrosion, great care must be taken to ensure complete coverage, without gaps, cracks, or pinhole defects.

Small defects can act as an "Achilles' heel", allowing corrosion to penetrate the interior and causing extensive damage even while the outer protective layer remains apparently intact for a period of time.

Painting either by roller or brush is more desirable for tight spaces; spray would be better for larger coating areas such as steel decks and waterfront applications.

Chemicals that inhibit corrosion include some of the salts in hard water (Roman water systems are known for their mineral deposits), chromates, phosphates, polyaniline, other conducting polymers, and a wide range of specially designed chemicals that resemble surfactants (i.e., long-chain organic molecules with ionic end groups).

Electrochemical conditions in the bath are carefully adjusted so that uniform pores, several nanometers wide, appear in the metal's oxide film.

[13] Controlled permeability formwork (CPF) is a method of preventing the corrosion of reinforcement by naturally enhancing the durability of the cover during concrete placement.

As rust displaces a much higher volume than the originating mass of iron, its build-up can also cause failure by forcing apart adjacent components.

Until 20–30 years ago, galvanized steel pipe was used extensively in the potable water systems for single and multi-family residents as well as commercial and public construction.

Today, these systems have long ago consumed the protective zinc and are corroding internally, resulting in poor water quality and pipe failures.

[18] The economic impact on homeowners, condo dwellers, and the public infrastructure is estimated at $22 billion as the insurance industry braces for a wave of claims due to pipe failures.

Due to its brittleness, such flaws cause a dramatic reduction in the strength of a glass object during its first few hours at room temperature.

Because of their large molecular weight, very little entropy can be gained by mixing a given mass of polymer with another substance, making them generally quite difficult to dissolve.

A more common and related problem is "swelling", where small molecules infiltrate the structure, reducing strength and stiffness and causing a volume change.

Conversely, many polymers (notably flexible vinyl) are intentionally swelled with plasticizers, which can be leached out of the structure, causing brittleness or other undesirable changes.

Mechanisms which break polymer chains are familiar to biologists because of their effect on DNA: ionizing radiation (most commonly ultraviolet light), free radicals, and oxidizers such as oxygen, ozone, and chlorine.

It causes an ion-selective depletion of near surface layers of glasses and gives an inverse-square-root dependence of corrosion rate with exposure time.