Forensic engineering

Forensic engineering has been defined as "the investigation of failures—ranging from serviceability to catastrophic—which may lead to legal activity, including both civil and criminal".

[1] The forensic engineering field is very broad in terms of the many disciplines that it covers, investigations that use forensic engineering are case of environmental damages to structures, system failures of machines, explosions, electrical, fire point of origin, vehicle failures and many more.

[2][1] It includes the investigation of materials, products, structures or components that fail or do not operate or function as intended, causing personal injury, damage to property or economic loss.

Many early rail accidents prompted the invention of tensile testing of samples and fractography of failed components.

[3] Vital to the field of forensic engineering is the process of investigating and collecting data related to the: materials, products, structures or components that failed.

[2] This involves: inspections, collecting evidence, measurements, developing models, obtaining exemplar products, and performing experiments.

First thing is when the forensic engineer arrives to the scene is to establish safety, they make sure that all the hazards have been dealt with an are safe to handle and be analyzed.

They also share common use of spectroscopy (infrared, ultraviolet, and nuclear magnetic resonance) to examine critical evidence.

For example, tire burn marks on a road surface can enable vehicle speeds to be estimated, when the brakes were applied and so on.

When a product fails for no obvious reason, SEM and Energy-dispersive X-ray spectroscopy (EDX) performed in the microscope can reveal the presence of aggressive chemicals that have left traces on the fracture or adjacent surfaces.

Thus an acetal resin water pipe joint suddenly failed and caused substantial damages to a building in which it was situated.

Analysis of the joint showed traces of chlorine, indicating a stress corrosion cracking failure mode.

The National Academy of Forensic Engineers (NAFE) was founded in 1982 by Marvin M. Specter, P.E., L.S., Paul E. Pritzker, P.E., and William A. Cox Jr., P.E.

Scanning electron microscopy or SEM showed that the nylon connector had fractured by stress corrosion cracking (SCC) due to a small leak of battery acid.

The nylon 6,6 had been attacked by the following reaction, which was catalyzed by the acid: Diesel fuel is especially hazardous on road surfaces because it forms a thin, oily film that cannot be easily seen by drivers.

Most manufacturing models will have a forensic component that monitors early failures to improve quality or efficiencies.

Furthermore, appliances, consumer products, medical devices, structures, industrial machinery, and even simple hand tools such as hammers or chisels can warrant investigations upon incidents causing injury or property damages.

New product development aims to eliminate defects by testing in the factory before launch, but some may occur during its early life.

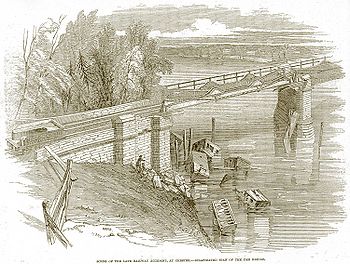

There are many examples of forensic methods used to investigate accidents and disasters, one of the earliest in the modern period being the fall of the Dee bridge at Chester, England.

It was finished in September 1846, and opened for local traffic after approval by the first Railway Inspector, General Charles Pasley.