Cycloid gear

To reduce friction, watch and clock movements require teeth and pinion leaves to be polished.

Also, since these mechanisms are expected to run constantly for years between servicing, lubrication can become contaminated with dirt and debris and effectively turn into grinding paste.

However, even well made cycloidal wheels and pinions are subject to this wear due to friction, dirt and oil migration from pivot bearings and other places.

This results in a dedendum which is a simple straight radial line, and therefore easy to shape and polish with hand tools.

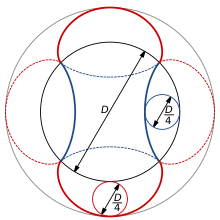

The addenda are not complete epicycloids, but portions of two different ones which intersect at a point, resulting in a "gothic arch" tooth profile.

A limitation of this gearform is that meshing is only precise on the pitch circle, with the result that where vibration is likely an involute profile is usually preferred.

Those involved include Gérard Desargues, Philippe de La Hire, Ole Rømer, and Charles Étienne Louis Camus.

If the diameter of this rolling circle is chosen to be infinitely large, a straight line is obtained.