Cylinder (locomotive)

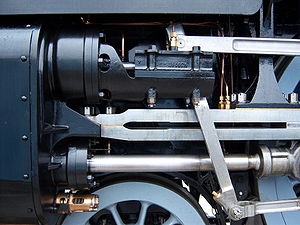

The cylinder casting includes other features such as (in the case of Stephenson's Rocket) valve ports and mounting feet.

[2] Renewable wearing surfaces were needed inside the cylinders and provided by cast-iron bushings.

Bolted joints came loose, cylinder castings and frames cracked and reduced the availability of the locomotive.

The next stage, for example Stephenson's Rocket, was to drive the wheels directly from steeply inclined cylinders placed at the back of the locomotive.

Inside cylinders give a more stable ride with less yaw or "nosing", but access for maintenance is more difficult.

As the cylinders are double-acting (i.e. fed with steam alternately at each end) this gives four impulses per revolution and ensures that there are no dead centres.

On inside-cylinder engines the valve gear is nearly always inside (between the frames), e.g. LMS Fowler Class 3F.