Cylindrical grinder

The cylindrical grinder owes much of its development from the onset of the Industrial Revolution, particularly to the advent of reliable, inexpensive steel production and later the improvement of the grinding wheel.

[1] The basis for the modern day cylindrical grinder was first built in the 1830s by two men working independently, Jonathan Bridges and James Wheaton .

[3] The Brown & Sharpe company in Providence, RI was one of the first builders of the Willcox & Gibbs Sewing Machine, one of the first piece of precision machinery to be used in a residential setting.

Joseph Brown believed that the shaft and needle bars of the sewing machine must be crafted from hardened tool steel.

A man in Waltham, Massachusetts, Ambrose Webster had created a small grinding machine in 1860 that contained all of the improvements Brown & Sharpe claimed to be their own original invention.

[4] Norton was an employee of Brown & Sharpe who quit the company with the desire to further pursue his belief that the cylindrical grinder is not merely a finishing tool but could be a staple of the machine shop.

He was acknowledged for his work on April 18, 1925 when he won The John Scott Medal and Premium for his invention of "accurate grinding devices of high power".

[4] The remainder of technological innovation applicable to the cylindrical grinder is almost identical and entangled in a sense, to the rest of machine tools.

The U.S. Air Force, looking for a faster, cheaper, and more efficient means of part and tool production for airplanes, played a large role in developing NC both politically and financially.

Now the machine was able to receive instruction from a computer which would give it precise directions on every imaginable dimension and measurement needed to produce the desired product.

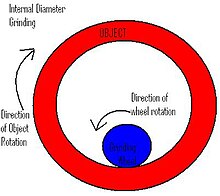

This effectively means the two surfaces will be moving opposite directions when contact is made which allows for a smoother operation and less chance of a jam up.