Depaneling

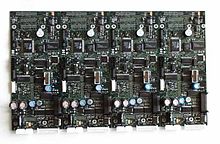

In order to increase the throughput of printed circuit board (PCB) manufacturing and surface mount (SMT) lines, PCBs are often arranged in a process called panelization so that they consist of many smaller individual PCBs that will be used in the final product.

The large panel is broken up or "depaneled" as a certain step in the process - depending on the product, it may happen right after SMT process, after in-circuit test (ICT), after soldering of through-hole elements, or even right before the final assembly of the PCB assembly (PCBA) into the enclosure.

The main reason of Breakaway Rail is to save the PCB boards from any damage at the edges.

[3] There are six main depaneling cutting techniques currently in use: This method is suitable for strain-resistant circuits (e.g. without SMD components).

The operator simply breaks the PCB, usually along a prepared V-groove line, with the help of a proper fixture.

The water stream is normally mixed with abrasive particles, helps in smooth cutting process.

Routers generate vibrations of the same frequency as their rotational speed (and higher harmonics), which might be important if there are vibration-sensitive components on the surface of the board.

At this wavelength the laser is capable of cutting, drilling and structuring on rigid and flex circuit substrates.

Advantages: accuracy, precision, low mechanical stress and flexible contour and cut capabilities.

Disadvantages: initial capital investment is often higher than traditional depaneling technologies, also the optimal board thickness is recommended to be no more than 1 mm.