Diffraction grating

Because of this, diffraction gratings are commonly used in monochromators and spectrometers, but other applications are also possible such as optical encoders for high-precision motion control[3] and wavefront measurement.

[8] The first human-made diffraction grating was made around 1785 by Philadelphia inventor David Rittenhouse, who strung hairs between two finely threaded screws.

In the 1860s, state-of-the-art diffraction gratings with small groove period (d) were manufactured by Friedrich Adolph Nobert (1806–1881) in Greifswald;[16] then the two Americans Lewis Morris Rutherfurd (1816–1892) and William B. Rogers (1804–1882) took over the lead.

on water, known as iridescence, is not caused by diffraction from a grating but rather by thin film interference from the closely stacked transmissive layers.

A grating has a 'zero-order mode' (where the integer order of diffraction m is set to zero), in which a ray of light behaves according to the laws of reflection (like a mirror) and refraction (like a lens), respectively.

As a result, the sum of the diffracted waves from the grating slits at the given observation point creates a peak, valley, or some degree between them in light intensity through additive and destructive interference.

When the difference between the light paths from adjacent slits to the observation point is equal to an odd integer-multiple of the half of the wavelength, l

Quantum electrodynamics (QED) offers another derivation of the properties of a diffraction grating in terms of photons as particles (at some level).

These probability amplitudes can be represented as a complex number or equivalent vector—or, as Richard Feynman simply calls them in his book on QED, "arrows".

The times these paths take are what determines the angle of the probability amplitude arrow, as they can be said to "spin" at a constant rate (which is related to the frequency of the photon).

The times of the paths near the classical reflection site of the mirror are nearly the same, so the probability amplitudes point in nearly the same direction—thus, they have a sizable sum.

However, a diffraction grating can be made out of this mirror, by scraping away areas near the edge of the mirror that usually cancel nearby amplitudes out—but now, since the photons don't reflect from the scraped-off portions, the probability amplitudes that would all point, for instance, at forty-five degrees, can have a sizable sum.

This particular description involves many simplifications: a point source, a "surface" that light can reflect off of (thus neglecting the interactions with electrons) and so forth.

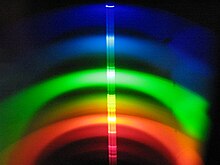

Each wavelength of input beam spectrum is sent into a different direction, producing a rainbow of colors under white light illumination.

The grating equation shows that the angles of the diffracted orders only depend on the grooves' period, and not on their shape.

Henry Joseph Grayson designed a machine to make diffraction gratings, succeeding with one of 120,000 lines to the inch (approx.

A copying technique can make high quality replicas from master gratings of either type, thereby lowering fabrication costs.

Semiconductor technology today is also used to etch holographically patterned gratings into robust materials such as fused silica.

In this way, low stray-light holography is combined with the high efficiency of deep, etched transmission gratings, and can be incorporated into high-volume, low-cost semiconductor manufacturing technology.

[26] In older versions of such gratings, environmental susceptibility was a trade-off, as the gel had to be contained at low temperature and humidity.

Typically, the photosensitive substances are sealed between two substrates that make them resistant to humidity, and thermal and mechanical stresses.

A new technology for grating insertion into integrated photonic lightwave circuits is digital planar holography (DPH).

DPH gratings are generated in computer and fabricated on one or several interfaces of an optical waveguide planar by using standard micro-lithography or nano-imprinting methods, compatible with mass-production.

Ordinary pressed CD and DVD media are every-day examples of diffraction gratings and can be used to demonstrate the effect by reflecting sunlight off them onto a white wall.

[28][29] Due to the sensitivity to the refractive index of the media, diffraction grating can be used as sensor of fluid properties.

[30] In a standard pressed vinyl record when viewed from a low angle perpendicular to the grooves, a similar but less defined effect to that in a CD/DVD is seen.

[31] Some everyday electronic components contain fine and regular patterns, and as a result readily serve as diffraction gratings.

Aside from this, the chemical structure of crystals can be thought of as diffraction gratings for types of electromagnetic radiation other than visible light, this is the basis for techniques such as X-ray crystallography.

Most commonly confused with diffraction gratings are the iridescent colors of peacock feathers, mother-of-pearl, and butterfly wings.

[38][39] However, natural gratings do occur in some invertebrate animals, like the peacock spiders,[40] the antennae of seed shrimp, and have even been discovered in Burgess Shale fossils.