Dry dock

The upper works included several decks with palatial cabins and saloons, containing thrones and couches all ready for imperial tours of inspection.

A large basin was excavated at the north end of the Chin-ming Lake capable of containing the dragon ships, and in it heavy crosswise beams were laid down upon a foundation of pillars.

Finally the beams and pillars were taken away, and the whole basin covered over with a great roof so as to form a hangar in which the ships could be protected from the elements and avoid the damage caused by undue exposure.

[2][3]The Greek author Athenaeus of Naucratis (V 204c-d) reports something that may have been a dry dock in Ptolemaic Egypt in the reign of Ptolemy IV Philopator (221-204 BC) on the occasion of the launch of the enormous Tessarakonteres rowing ship.

And in the trench he built props of solid stone five cubits deep, and across them he laid beams crosswise, running the laces whole width of the trench, at four cubits' distance from one another; and then making a channel from the sea he filled all the space which he had excavated with water, out of which he easily brought the ship by the aid of whatever men happened to be at hand; then closing the entrance which had been originally made, he drained the water off again by means of engines (organois); and when this had been done the vessel rested securely on the before-mentioned cross-beams.

An account of 1434 described how a site near Southampton with a bottom of soft mud was selected for the warship Grace Dieu, so that the hull would bed itself in and remain upright at low tide.

[8] The first early modern purpose-built European and oldest surviving dry dock still in use was commissioned by Henry VII of England at HMNB Portsmouth in 1495.

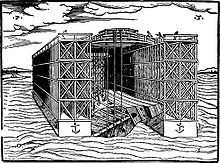

Possibly the earliest description of a floating dock comes from a small Italian book printed in Venice in 1560, called Descrittione dell'artifitiosa machina.

[13] In the booklet, an unknown author asks for the privilege of using a new method for the salvaging of a grounded ship and then proceeds to describe and illustrate his approach.

The largest roofed dry dock is at the German Meyer Werft Shipyard in Papenburg, Germany, it is 504 m long, 125 m wide and stands 75 m tall.

An advantage of covered dry docks is that work can take place in any weather; this is frequently used by modern shipyards for construction especially of complex, high-value vessels like cruise ships, where delays would incur a high cost.

For smaller boats, one-piece floating dry docks can be constructed or converted out of an existing obsolete barge, potentially coming with their own bow and steering mechanism.

The latter, an Advance Base Sectional Dock which saw action in Guam, was mothballed near Norfolk, Virginia, and was eventually towed to Portland, Maine, to become part of Bath Iron Works' repair facilities.

For example, the dry dock on the artificial island of Neeltje-Jans was used for the construction of the Oosterscheldekering, a large dam in the Netherlands that consists of 65 concrete pillars weighing 18,000 tonnes each.