Dynamite

After some bad business deals in Sweden, in 1838 Immanuel moved his family to Saint Petersburg, where Alfred and his brothers were educated privately under Swedish and Russian tutors.

At the age of 17, Alfred Nobel was sent abroad for two years; in the United States he met Swedish engineer John Ericsson and in France studied under famed chemist Théophile-Jules Pelouze and his pupil Ascanio Sobrero, who had first synthesized nitroglycerin in 1847.

[2] In 1857, Nobel filed the first of several hundred patents, mostly concerning air pressure, gas and fluid gauges, but remained fascinated with nitroglycerin's potential as an explosive.

To solve this problem, Nobel sought to combine it with another substance that would make it safe for transport and handling but would not reduce its effectiveness as an explosive.

Finally, he tried diatomaceous earth, which is fossilized algae, that he brought from the Elbe River near his factory in Hamburg, which successfully stabilized the nitroglycerin into a portable explosive.

[citation needed] Modern packaging helps eliminate this by placing the dynamite into sealed plastic bags and using wax-coated cardboard.

Shock resistance tests are usually carried out with a drop-hammer: about 100 mg of explosive is placed on an anvil, upon which a weight of between 0.5 and 10 kg (1 and 22 lb) is dropped from different heights until detonation is achieved.

Some workers died, but the loss of life was limited by the modular design of the factory and its earth works, and the planting of trees that directed the blasts upward.

[11] Dynamite was first manufactured in the US by the Giant Powder Company of San Francisco, California, whose founder had obtained the exclusive rights from Nobel in 1867.

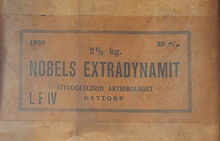

The only facility producing it is located in Carthage, Missouri, but the material is purchased from Dyno Nobel by other manufacturers who put their labels on the dynamite and boxes.

TNT is a second-generation castable explosive adopted by the military, while dynamite, in contrast, has never been popular in warfare because it degenerates quickly under severe conditions and can be detonated by either fire or a wayward bullet.

The German armed forces adopted TNT as a filling for artillery shells in 1902, some 40 years after the invention of dynamite, which is a first-generation phlegmatized explosive primarily intended for civilian earthmoving.

TNT has never been popular or widespread in civilian earthmoving, as it is considerably more expensive and less powerful by weight than dynamite,[13] as well as being slower to mix and pack into boreholes.

TNT's primary asset is its remarkable insensitivity and stability: it is waterproof and incapable of detonating without the extreme shock and heat provided by a blasting cap (or a sympathetic detonation); this stability also allows it to be melted at 81 °C (178 °F), poured into high explosive shells and allowed to re-solidify, with no extra danger or change in the TNT's characteristics.

For example, high-explosive 65% Extra dynamite has a weight strength of 65% ammonium nitrate and 35% "dope" (the absorbent medium mixed with the stabilizers and additives).

- Diatomaceous earth (or any other type of absorbent material) soaked in nitroglycerin .

- Protective coating surrounding the explosive material.

- Blasting cap .

- Electrical cable (or fuse ) connected to the blasting cap.