K-25

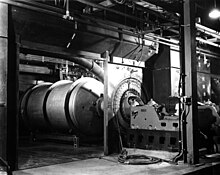

K-25 was the codename given by the Manhattan Project to the program to produce enriched uranium for atomic bombs using the gaseous diffusion method.

[4] Niels Bohr and John Archibald Wheeler applied the liquid drop model of the atomic nucleus to explain the mechanism of nuclear fission.

[10][11][12] At the University of Birmingham in Britain, the Australian physicist Mark Oliphant assigned two refugee physicists—Otto Frisch and Rudolf Peierls—the task of investigating the feasibility of an atomic bomb, ironically because their status as enemy aliens precluded their working on secret projects like radar.

[13] Their March 1940 Frisch–Peierls memorandum indicated that the critical mass of uranium-235 was within an order of magnitude of 10 kilograms (22 lb), which was small enough to be carried by a bomber aircraft of the day.

[14] In April 1940, Jesse Beams, Ross Gunn, Fermi, Nier, Merle Tuve and Harold Urey had a meeting at the American Physical Society in Washington, D.C. At the time, the prospect of building an atomic bomb seemed dim, and even creating a chain reaction would likely require enriched uranium.

[17] Before this could be done, the Special Alloyed Materials (SAM) Laboratories at Columbia University and the Kellex Corporation had to overcome formidable difficulties to develop a suitable barrier.

In July 1941, an Office of Scientific Research and Development (OSRD) contract was awarded to Columbia University to study gaseous diffusion.

Because the scope of the project was not well defined, Kellogg and the Manhattan District agreed to defer any financial details to a later, cost-plus contract, which was executed in April 1944.

[25] For security reasons, the Army had Kellogg establish a wholly-owned subsidiary, the Kellex Corporation, so the gaseous diffusion project could be kept separate from other company work.

[25][30] The codename "K-25" was a combination of the "K" from Kellex, and "25", a World War II-era code designation for uranium-235 (an isotope of element 92, mass number 235).

The director of the Manhattan Project, Brigadier General Leslie R. Groves Jr., gave the contract to build the diffusers to Chrysler.

The electroplating process required over 50,000 square feet (4,600 m2) of floor space, several thousand workers and a complicated air filtration system to ensure the nickel was not contaminated.

Then Judson Swearingen at the Elliott Company came up with a revolutionary and promising design that was mechanically stable with seals that would contain the gas.

Libby made progress on understanding the chemistry of uranium hexafluoride, leading to ideas on how to prevent corrosion and plugging.

Chemical researchers at the SAM Laboratories studied fluorocarbons, which resisted corrosion and could be used as lubricants and coolants in the gaseous diffusion plant.

On 13 August Groves informed the Military Policy Committee (the senior committee that steered the Manhattan Project) that gaseous diffusion enrichment in excess of fifty percent was probably infeasible, and the gaseous diffusion plant would be limited to producing product with a lower enrichment which could be fed into the calutrons of the Y-12 electromagnetic plant.

To Frazier Groff and other researchers at Bakelite's laboratories in Bound Brook, New Jersey, it seemed that Nix was not taking advantage of the latest techniques, and they began their own development efforts.

At a meeting at Columbia with the Army in attendance on 20 October 1943, Keith proposed switching the development effort to the Johnson barrier.

With plenty of nickel to work with, by April 1944 both pilot plants were producing barriers of acceptable quality at a 45 percent rate.

[48] Kellex engaged another construction company, Ford, Bacon & Davis, to build the fluorine and nitrogen facilities, and the conditioning plant.

The Kellex engineers were also attracted to the idea of being able to generate the variable frequency current required by the gaseous diffusion process without complicated transformers.

[54] To obtain the fourteen turbine generators needed, Groves had to use the Manhattan Project's priority to overrule Julius Albert Krug, the director of the Office of War Utilities.

Owing to the hazardous nature of fluorine, it was decided that shipping it across the United States was inadvisable and it should be manufactured on site at the Clinton Engineer Works.

Groves initially approved this but later canceled it in favor of a 540-stage side feed unit, which became known as K-27, which could process a slightly enriched product.

[73] Part of the K-300 complex was taken over by Union Carbide in August 1944 and was run as a pilot plant, training operators and developing procedures, using nitrogen instead of uranium hexafluoride until October 1944, and then perfluoroheptane until April 1945.

This presented a problem, because Y-12 was not equipped to handle feed that was so highly enriched, but the Los Alamos Laboratory required 95 percent.

[91] After some deliberation, with opinions sought and obtained from Percival Keith, Norris Bradbury, Darol Froman, Elmer E. Kirkpatrick, Kenneth Nichols and Edward Teller,[92] it was decided that this could be done safely if appropriate precautions were taken.

When German scientists and engineers were released from Soviet captivity in the mid-1950s, the West became aware of the ultra centrifuge design and began shifting uranium enrichment to this much more efficient process.

As centrifuge technology advanced, it became possible to carry out uranium enrichment on a smaller scale without the vast resources that were necessary to build and operate 1940s and 1950s "K" and "Y" style separation plants, a development which had the effect of increasing nuclear proliferation concerns.

[111] US Senator Lamar Alexander and US Congressman Chuck Fleischmann joined 1,500 workers to watch the final wall come down on 30 August 2016.