Electrodynamic suspension

This induces eddy currents in the conductors that creates a repulsive magnetic field which holds the two objects apart.

In this early configuration by Bedford, Peer, and Tonks from 1939, an aluminum plate is placed on two concentric cylindrical coils, and driven with an AC current.

[1] In the 1950s, a technique was developed where small quantities of metal were levitated and melted by a magnetic field of a few tens of kHz.

Further development included replacing the single-phase energising current with a linear induction motor which combined levitation and thrust.

They were also able to break the levitator primary into convenient sections which made it easier to build and transport.

When they are displaced off-center, current flows and a strong field is generated by the coil which tends to restore the spacing.

A major advantage of the repulsive maglev systems is that they are naturally stable - minor narrowing in distance between the track and the magnets creates strong forces to repel the magnets back to their original position, while a slight increase in distance greatly reduces the force and again returns the vehicle to the right separation.

Since a train may stop at any location, due to equipment problems for instance, the entire track must be able to support both low-speed and high-speed operation.

Since the field and potentials are out of phase, both attractive and repulsive forces are produced, and it might be expected that no net lift would be generated.

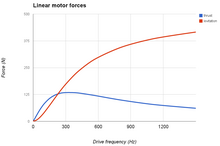

Thus at low frequencies, the phases are largely orthogonal and the currents lower, and no significant lift is generated.

However, there are also eddy currents due to the finite size of conductors used in the coils, and these continue to grow with frequency.

Since the energy stored in the air gap can be calculated from HB/2 (or μ0H2/2) times air-gap volume, the force applied across the air gap in the direction perpendicular to the load (viz., the force that directly counteracts gravity) is given by the spatial derivative (= gradient) of that energy.

Given the details of the applicable hysteresis loop, frequency-dependent variability of behavior should be of minimal importance for those magnetic materials that are likely to be deployed.

[5] Alternatively, addition of lightweight tuned mass dampers can prevent oscillations from being problematic.