Energy harvesting

For example, temperature gradients exist from the operation of a combustion engine and in urban areas, there is a large amount of electromagnetic energy in the environment due to radio and television broadcasting.

Another application is in wearable electronics, where energy-harvesting devices can power or recharge cell phones, mobile computers, and radio communication equipment.

All of these devices must be sufficiently robust to endure long-term exposure to hostile environments and have a broad range of dynamic sensitivity to exploit the entire spectrum of wave motions.

Scavenging energy from ambient vibrations, wind, heat, or light could enable smart sensors to function indefinitely.

In general, for motion-powered devices, typical values are a few μW/cm3 for human body-powered applications and hundreds of μW/cm3 for generators powered by machinery.

[11] Another motivation for energy harvesting is the potential to address the issue of climate change by reducing greenhouse gas emissions and fossil fuel consumption.

Notable examples include battery-free game boys [13] and other toys,[14] which showcase the potential of devices powered by the energy generated from user actions, such as pressing buttons or turning knobs.

[9] This is now commonplace in passive radio-frequency identification (RFID) systems, but the Safety and US Federal Communications Commission (and equivalent bodies worldwide) limit the maximum power that can be transmitted this way to civilian use.

Multiple companies are developing these technologies, which can operate in low-light environments, such as HVAC ducts, and can be scaled and optimized for the energy requirements of specific applications.

[20][21] Photovoltaic (PV) energy harvesting wireless technology offers significant advantages over wired or solely battery-powered sensor solutions: virtually inexhaustible sources of power with little or no adverse environmental effects.

Indoor PV harvesting solutions have to date been powered by specially tuned amorphous silicon (aSi)a technology most used in Solar Calculators.

Electrons released on impact escape to the layer of TiO2 and from there diffuse, through the electrolyte, as the dye can be tuned to the visible spectrum much higher power can be produced.

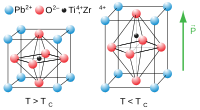

Except in rare instances the piezoelectric effect operates in AC requiring time-varying inputs at mechanical resonance to be efficient.

Most piezoelectric electricity sources produce power on the order of milliwatts, too small for system application, but enough for hand-held devices such as some commercially available self-winding wristwatches.

DARPA has funded efforts to harness energy from leg and arm motion, shoe impacts, and blood pressure for low level power to implantable or wearable sensors.

Multiple other nanostructures have been exploited to build an energy-harvesting device, for example, a single crystal PMN-PT nanobelt was fabricated and assembled into a piezoelectric energy harvester in 2016.

[29] Besides, as the vibration of motion from human comes in three directions, a single piezoelectric cantilever based omni-directional energy harvester is created by using 1:2 internal resonance.

[36] Arman Hajati and Sang-Gook Kim invented the Ultra Wide-Bandwidth micro-scale piezoelectric energy harvesting device by exploiting the nonlinear stiffness of a doubly clamped microelectromechanical systems (MEMSs) resonator.

The stretching strain in a doubly clamped beam shows a nonlinear stiffness, which provides a passive feedback and results in amplitude-stiffened Duffing mode resonance.

[38][39][40] In 2018, Soochow University researchers reported hybridizing a triboelectric nanogenerator and a silicon solar cell by sharing a mutual electrode.

[50] PZT thin films have attracted attention for applications such as force sensors, accelerometers, gyroscopes actuators, tunable optics, micro pumps, ferroelectric RAM, display systems and smart roads,[50] when energy sources are limited, energy harvesting plays an important role in the environment.

Pyroelectricity requires time-varying inputs and suffers from small power outputs in energy harvesting applications due to its low operating frequencies.

[57] It has also been established theoretically that pyroelectric conversion based on heat regeneration using an oscillating working fluid and the Olsen cycle can reach Carnot efficiency between a hot and a cold thermal reservoir.

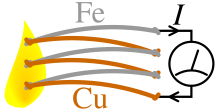

Today, due to knowledge of the Seebeck and Peltier effects, thermoelectric materials can be used as heaters, coolers and generators (TEGs).

Standard thermoelectric modules manufactured today consist of P- and N-doped bismuth-telluride semiconductors sandwiched between two metallized ceramic plates.

The resulting devices are self-biasing, and can directly charge batteries, or can produce exponentially growing voltages on storage capacitors, from which energy can be periodically extracted by DC/DC converters.

[65] Magnets wobbling on a cantilever are sensitive to even small vibrations and generate microcurrents by moving relative to conductors due to Faraday's law of induction.

[66] One of the major limitations of the magnetic vibration energy harvester developed at University of Southampton is the size of the generator, in this case approximately one cubic centimeter, which is much too large to integrate into today's mobile technologies.

Examples include products developed by Swedish company ReVibe Energy, a technology spin-out from Saab Group.

This type of complementary balanced energy harvesting has the potential to increase reliability of wireless sensor systems for structural health monitoring.