Engineering controls

Following the hierarchy is intended to lead to the implementation of inherently safer systems, ones where the risk of illness or injury has been substantially reduced.

They also ideally do not interfere with productivity and ease of processing for the worker, because otherwise the operator may be motivated to circumvent the controls.

Engineering control approaches are often oriented towards reducing inhalation exposure through ventilation and isolation of the toxic material.

However, isolation can also be useful for preventing skin and eye contact as well, reducing reliance on personal protective equipment which should be the control of last resort.

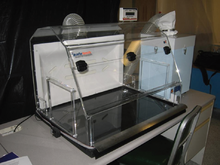

[9]: 12 Examples of local exhaust systems include fume hoods, vented balance enclosures, and biosafety cabinets.

[11]: 19–24 Low-turbulence balance enclosures were initially developed for the weighing of pharmaceutical powders and are also used for nanomaterials; these provide adequate containment at lower face velocities, typically operating at 65–85 fpm.

[11]: 13 Several control verification techniques can be used to assess room airflow patterns and verify the proper operation of LEV systems.

It is considered important to confirm that an LEV system is operating as designed by regularly measuring exhaust airflows.

[9]: 50–52, 59 Standardized testing and certification procedures such as ANSI Z9.5 and ASHRAE 110 can be used, as can qualitative indicators of proper installation and functionality such as inspection of gaskets and hoses.

[9]: 59–60 [13]: 14–15 Containment refers to the physical isolation of a process or a piece of equipment to prevent the release of the hazardous material into the workplace.

One of the most common flexible isolation systems is glovebox containment, which can be used as an enclosure around small-scale powder processes, such as mixing and drying.

[11]: 24–28 Another non-ventilation control used in this industry is the continuous liner system, which allows the filling of product containers while enclosing the material in a polypropylene bag.

[13]: 9–11 [15] Antistatic devices can be used when handling particulates including nanomaterials to reduce their electrostatic charge, making them less likely to disperse or adhere to clothing.

Ergonomists and industrial hygienists aim to prevent musculoskeletal disorders and soft tissue injuries by fitting the workers to their work space.

Tools, lighting, tasks, controls, displays, and equipment as well as the employee's capabilities and limitations must all be considered to create an ergonomically appropriate workplace.

These barricades are placed near an edge where a fall hazard can occur, or to surround a weak surface (such as a skylight on a roof) that may break when stepped on.

[25] This article incorporates public domain material from websites or documents of the National Institute for Occupational Safety and Health.