English Electric

Its products were later expanded to include consumer electronics, nuclear reactors, guided missiles, military aircraft and mainframe computers.

[3] Aiming to turn their employees and other assets to peaceful productive purposes, the owners of a series of businesses decided to merge them forming The English Electric Company Limited in December 1918.

[5] Initially J H Mansell of Coventry Ordnance Works, John Pybus of Phoenix Dynamo Manufacturing and W Rutherford of Dick, Kerr were joint managing directors.

[6]The five previously independent major operations under their control had these principal capabilities: Together these businesses covered the whole field of electrical machinery from the smallest fan motor to the largest turbo-generator.

Though English Electric products were indeed in heavy demand, potential buyers were unable to raise the necessary capital funds.

In the event, an American syndicate fronted by Lazard Brothers and Co. bankers came up with the new capital, but left control in the hands of the previous shareholders.

[16] Mensforth had been taken away from his position as general manager of American Westinghouse Trafford Park Manchester, where George Nelson had been his apprentice, in 1919 by the Minister of Transport.

[27] The chairman reported to shareholders that though both Dick, Kerr and Phoenix were involved in the aircraft business during and shortly after the previous war the problems had so changed they were now completely new to the company.

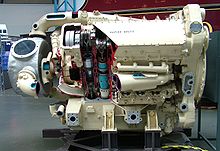

[31] Napier's Sabre engines were used in Typhoon and Tempest aircraft and Lion engines in Motor Torpedo Boats[29][30] The Stafford works made thousands of Covenanter, Centaur and Cromwell tanks as well as precision instruments for aircraft, electric propulsion and electrical equipment.The Rugby works made Diesel engines for ships, submarines and locomotives, steam turbines for ships and turbo-alternator sets for power stations.Bradford made electric generators for ships' auxiliaries and a wide variety of other naval and aviation material.

[33] In September 1945, details were released of the Vampire jet, the fastest British aircraft with a top speed of 548 mph.

The aircraft was built by English Electric at its Preston works, the Frank Halford designed Goblin jet engine, the world's most powerful, by de Havilland in London.

Between 1951 and 1959, English Electric supplied the National Coal Board with five 51-ton, 400 hp electric shunting locomotives for use on the former Harton Coal Company System at South Shields (which had been electrified by Siemens in 1908) to supplement the existing fleet of ten ageing Siemens and AEG locomotives.

English Electric took over Vulcan Foundry and Robert Stephenson and Hawthorns,[35] both with substantial railway engineering pedigrees, in 1955.

Most of these classes of locomotive gave long service to British Rail and its successor train operating companies, some still being active well into the 21st century.

With War in Europe looming, English Electric was instructed by the Air Ministry to construct a "shadow factory" at Samlesbury Aerodrome in Lancashire to build Handley Page Hampden bombers.

In 1940, a second factory was built on the site and the runway was extended to allow for construction of the Handley Page Halifax four-engined heavy bomber to begin.

Post-war, English Electric invested heavily in this sector, moving design and experimental facilities to the former RAF Warton near Preston in 1947.

This investment led to major successes with the Lightning and Canberra, the latter serving in a multitude of roles from 1951 until mid-2006 with the Royal Air Force.

At the end of the war, English Electric started production under licence of the second British jet fighter, the de Havilland Vampire, with 1,300 plus built at Samlesbury.

7SRL Diesel alternator sets being installed

the Saateni Power Station, Zanzibar 1955