Ethanol fuel

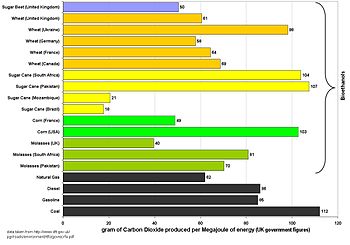

Agricultural feedstocks are considered renewable because they get energy from the sun using photosynthesis, provided that all minerals required for growth (such as nitrogen and phosphorus) are returned to the land.

Ethanol can be produced from a variety of feedstocks such as sugar cane, bagasse, miscanthus, sugar beet, sorghum, grain, switchgrass, barley, hemp, kenaf, potatoes, sweet potatoes, cassava, sunflower, fruit, molasses, corn, stover, grain, wheat, straw, cotton, other biomass, as well as many types of cellulose waste and harvesting, whichever has the best well-to-wheel assessment.

The first process, used in many early fuel ethanol plants, is called azeotropic distillation and consists of adding benzene or cyclohexane to the mixture.

Another early method, called extractive distillation, consists of adding a ternary component that increases ethanol's relative volatility.

A two-stage counter-current setup of mixer-settler tanks can achieve complete recovery of ethanol into the fuel phase, with minimal energy consumption.

This high miscibility with water means that ethanol cannot be efficiently shipped through modern pipelines, like liquid hydrocarbons, over long distances.

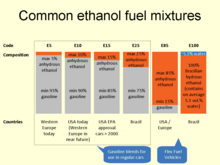

[37] The EPA-rated mileage of current United States flex-fuel vehicles[38] should be considered when making price comparisons, but E85 is a high performance fuel, with an octane rating of about 94–96, and should be compared to premium.

[46][47] In March 2009 Volkswagen do Brasil launched the Polo E-Flex, the first Brazilian flex fuel model without an auxiliary tank for cold start.

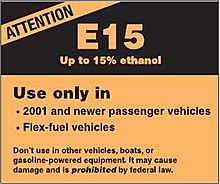

[51] In January 2011 the U.S. Environmental Protection Agency (EPA) issued a waiver to authorize up to 15% of ethanol blended with gasoline (E15) to be sold only for cars and light pickup trucks with a model year of 2001 or newer.

This method is backed up by advanced knock sensors – used in most high performance gasoline engines regardless of whether they are designed to use ethanol or not – that detect pre-ignition and detonation.

From March 2021, auto manufacturers are required to indicate the ethanol compatibility of new vehicles and engines must be optimally designed to use 20% ethanol-blended fuel.

The engines, made by Scania, have a modified compression ratio, and the fuel (known as ED95) used is a mix of 93.6% ethanol and 3.6% ignition improver, and 2.8% denaturants.

A 2004 MIT study and an earlier paper published by the Society of Automotive Engineers identified a method to exploit the characteristics of fuel ethanol substantially more efficiently than mixing it with gasoline.

The problems of water absorption into pre-mixed gasoline (causing phase separation), supply issues of multiple mix ratios and cold-weather starting are also avoided.

[58][59] In a 2008 study, complex engine controls and increased exhaust gas recirculation allowed a compression ratio of 19.5 with fuels ranging from neat ethanol to E50.

The vehicle would include a tank for a blend of water and ethanol, which is fed into an onboard reformer that splits it into pure hydrogen and carbon dioxide.

[65] Brazil's ethanol fuel program uses modern equipment and cheap sugarcane as feedstock, and the residual cane-waste (bagasse) is used to produce heat and power.

A study by atmospheric scientists at Stanford University found that E85 fuel would increase the risk of air pollution deaths relative to gasoline by 9% in Los Angeles, US: a very large, urban, car-based metropolis that is a worst-case scenario.

Gas chromatograph studies were performed of ambient air in São Paulo, Brazil, and compared to Osaka, Japan, which does not burn ethanol fuel.

[78] The January 2006 Science article from UC Berkeley's ERG, estimated reduction from corn ethanol in GHG to be 13% after reviewing a large number of studies.

[81] As an example, converting grass lands to corn production for ethanol takes about a century of annual savings to make up for the GHG released from the initial tilling.

[82] There are claims that land for ethanol production is acquired through deforestation, while others have observed that areas currently supporting forests are usually not suitable for growing crops.

Instead of utilizing only the starch by-products from grinding wheat and other crops, cellulosic ethanol production maximizes the use of all plant materials, including gluten.

This approach would have a smaller carbon footprint because the amount of energy-intensive fertilisers and fungicides remain the same for higher output of usable material.

Fast growing species like switchgrass can be grown on land not suitable for other cash crops and yield high levels of ethanol per unit area.

According to a 2008 analysis by Iowa State University, the growth in US ethanol production has caused retail gasoline prices to be US$0.29 to US$0.40 per gallon lower than would otherwise have been the case.

[115] In 2011, the three national NASCAR stock car series mandated a switch from gasoline to E15, a blend of Sunoco GTX unleaded racing fuel and 15% ethanol.

[117] Project Gaia is a U.S. non-governmental, non-profit organization involved in the creation of a commercially viable household market for alcohol-based fuels in Ethiopia and other countries in the developing world.

Targeting poor and marginalized communities that face health issues from cooking over polluting fires, Gaia currently works in Ethiopia, Nigeria, Brazil, Haiti, and Madagascar, and is in the planning stage of projects in several other countries.

[120] Other potential feedstocks are municipal waste, recycled products, rice hulls, sugarcane bagasse, wood chips, switchgrass and carbon dioxide.