Feedwater heater

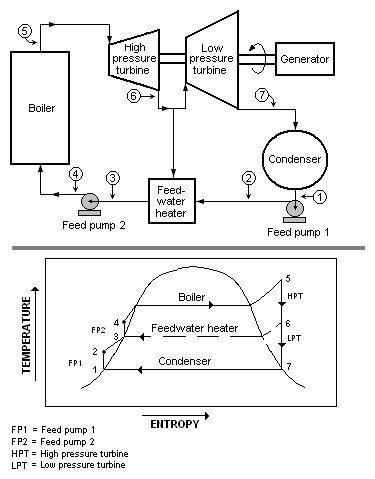

[4] This reduces plant operating costs and also helps to avoid thermal shock to the boiler metal when the feedwater is introduced back into the steam cycle.

However, the extracted steam (which is most likely almost fully condensed after heating the feedwater) must then be throttled to the condenser pressure, an isenthalpic process that results in some entropy gain with a slight penalty on overall cycle efficiency: Many power plants incorporate a number of feedwater heaters and may use both open and closed components.

In fossil-fuel plants, the economizer uses the lowest-temperature flue gas from the furnace to heat the water before it enters the boiler proper.

This allows for the heat transfer between the furnace and the feedwater to occur across a smaller average temperature gradient (for the steam generator as a whole).

However, the Combustion Engineering System 80+ nuclear plant design and its evolutionary successors, (e.g. Korea Electric Power Corporation's APR-1400) incorporate an integral feedwater economizer.