Field hockey stick

These sticks usually contain a combination of fibreglass, aramid fiber and carbon fibre in varying proportions according to the characteristics (flexibility; stiffness; resistance to impact and abrasion) required.

After centuries of different variations of field hockey (including a version in England, sometime prior to 1860, in which, because of the very hilly heathland area in which it was played, a rubber cube and not a ball was used), the game became more organised and regularised.

(The game in its modern form was apparently brought to India by the British Army, although there does not appear to be any specific evidence of this.

At that time the stick head was very long (in excess of 12"—300 mm) and made from an indigenous British timber, ash.

Secondly (top right), if the handle of the stick is kept at exactly the same angle and rotated, a horizontal adjustment is necessary to bring the reversed head to a position where contact will be made with the ball.

The fourth figure (bottom right) demonstrates that to get good contact with the ball on a larger area of the reversed head, it is necessary to move the handle much nearer to the vertical.

(This left side position was compounded in difficulty with a very severe interpretation of "obstruction", which prohibited shielding of the ball from an opponent.

Reversed stick hitting, pushing and flicking would be short range skills and difficult to do accurately, if at all, especially when moving at speed.

Although there was a development of "system hockey" that overcame the stick/ball skill deficiencies of the Europeans compared with India and Pakistan at the time, it was not as fluid as the kind of one and two touch passing game common in soccer and that ideal was (and still is) a long way off.

This new design was possible because of the development of epoxy resin glues that did not require perfectly dry timber for bonding and curing to a strength that could cope with the immense stresses placed on a stick head when a hockey ball is struck with it.

After the arrival of the laminations, some brands were offering as many as ten different shapes or styles of stick head on the traditional shaft.

In the early 1990s there were an astonishing number and variety of hockey sticks on offer compared with what had been available ten years earlier.

There were also hockey sticks with metal handles and inserted plywood heads (made by the American company Eastons, better known for making baseball bats), as well as the wide range of one piece head sticks still produced and an expanding range of laminated midi and laminated shorties.

The metal handled sticks were later banned for "safety reasons", in what was widely regarded as a political move by the FIH.

It will be appreciated after a glance at the illustration of the 'English' style hockey stick that stopping a ball on the ground with the handle held vertically would not be easy.

Stopping the ball closer to the toe of the stick is acceptable but not optimal, as adjustment, which takes time, is necessary before the next intended action.

A stick with a set-back head and toe-side protrusion, with the handle positioned vertically, covers substantially more of the ball and can reduce off heel deflection errors in stopping.

In the mid-90s the "hook" head style hockey stick was relaunched, this time by the former German U21 International player Thomas Kille.

Manufacturers became much more aware of the look of their products and hockey sticks sold, particularly to new players, as much on colour and fashion as strength and usability.

The vertical height of the toe was approximately 80 mm (dotted line) Fig.1 and it was of almost uniform thickness with the remainder of the stick head.

There was not a significant impact but it (and others) added to the general confusion, as apparently 'everyone and his dog' were presenting new ideas in head shape.

The 'Hook' certainly felt out of rotational balance, especially to those who had been playing with short-head sticks that had been made with a very thin toe, so as to concentrate the weight of the head closer to the shaft.

Previously the only restraint on the configuration of a hockey stick was that it had to pass through a ring of 2" diameter (later adjusted to 51 mm—2 in rounded up to the nearest millimeter).

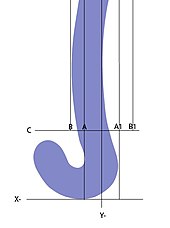

The length of the Head (or toe) along the X- axis has varied enormously, especially since the Second World War and again after the introduction of the timber lamination process in the early 1980s.

The maximum permitted width of the handle (51 mm) is illustrated in the diagram by the distance between the dotted lines A-A and A1-A1.

The sample illustrated does not reach the line A1A1 on the 'heel edge' and the Y axis is not central to the shaft, which raises the question "How is the stick positioned for measurement of permitted deviation."

The placement of the maximum bow along the length of handle has now been specified in the Rules of Hockey at 20 cm above the head (the line C-C).

The result of the sloping of the face side is to put one edge of it closer than 25 mm to the flat surface and permit a much deeper bow than would otherwise be possible.

The effect of placing the maximum bow lower down the handle was to increase the angle at which the stick head was presented to the ball.

To deal with the problem of head presentation some players use a low 'roundhouse' style of hitting, rather than an upright style and may also employ sweep-hits or slap-hitting of the ball (the difference being the positioning of the hands, sweep hits are generally made with the hands together at the top of the stick and with the base of the stick head in contact with the ground, while slap-hits are usually made with the hands in the more spread dribbling grip and the stick head is not necessarily in contact with the ground, but it may be), either sweep or slap type strokes give greater control over the angle of the face of the stick as it makes contact with the ball and are often the preferred strokes when passing the ball over longer distances (over shorter distances—less than 20 m—a push stroke is often preferred).