Sand filter

They are usually used to separate small amounts (<10 parts per million or <10 g per cubic metre) of fine solids (<100 micrometres) from aqueous solutions.

In some applications it is necessary to pre-treat the effluent flowing into a sand bed to ensure that the particulate solids can be captured.

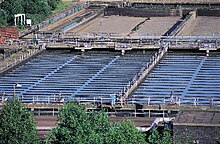

Large process plants have also a system implemented to evenly distribute the raw water to the filter.

During filter ripening the effluent might not meet quality criteria and must be reinjected at previous steps in the plant.

Backwash water may partially be reinjected in front of the filter process and generated sewage needs to be discarded.

Smaller sand grains provide more surface area and therefore a higher decontamination of the inlet water, but it also requires more pumping energy to drive the fluid through the bed.

A compromise is that most rapid pressure sand bed filters use grains in the range 0.6 to 1.2 mm although for specialist applications other sizes may be specified.

Larger feed particles (>100 micrometres) will tend to block the pores of the bed and turn it into a surface filter that blinds rapidly.

[5]: 302–303 Guidance on the design of rapid sand bed filters suggests that they should be operated with a maximum flow rate of 9 m3/m2/hr (220 US gal/ft2/hr).

[7] The build-up of particulate solids causes an increase in the pressure lost across the bed for a given flow rate.

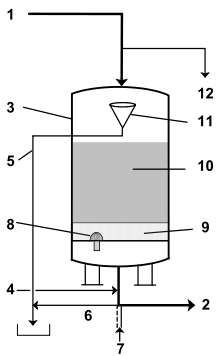

When the pressure loss or flow is unacceptable and the filter is not working effectively any longer, the bed is remove the accumulated particles.

The backwash fluid is pumped backwards through the bed until it is fluidized and has expanded by up to about 30% (the sand grains start to mix and as they rub together they drive off the particulate solids).

The smaller particulate solids are washed away with the backwash fluid and captured usually in a settling tank.

[5]: 224–235 Small amounts of sand can be lost in the backwashing process and the bed may need to be topped up periodically.

During the process of filtration, raw water can percolate through the porous sand medium, stopping and trapping organic material, bacteria, viruses and cysts such as Giardia and Cryptosporidium.

Slow sand filters are a good option for limited budget operations as the filtration is not using any chemicals and requires little or no mechanical assistance.

But the filtering layers will be always arranged by density, heavier compounds will be settled in the bottom, while the lighter ones will be located on top.

A very common arrangement for these filers is composed of: anthracite on top, sand and garnet, with a support of gravel at the bottom.

Passing flocculated water through a rapid gravity sand filter strains out the floc and the particles trapped within it, reducing numbers of bacteria and removing most of the solids.

Moreover, the different types of operation modes: rapid, slow and Upflow, allow some flexibility to adapt the filtration method to the necessities and requirements of the users.

Sand filters allow a high efficiency for color and microorganisms removal, and as they are very simple, operating costs are very low.

The main limitations of this technology would be related to the clogging, that is, the obstruction of the filter media, which requires a significant amount of water to carry out the backflush operation and the use of chemicals in the pretreatment.

Furthermore, slow sand filters usually require larger land areas compared to the rapid flow, especially if the raw water is highly contaminated.

Aforementioned processes such as filter ripening and backwashing influence not only the water quality but also the time needed for the full treatment.

From the chemical perspective, varying raw water qualities and changes in the temperature effect, already at the entrance to the plant, the efficiency of the treatment process.

[6] Sand filters are used in various sectors and processes, where far-reaching removal of suspended matter from water or wastewater is required.