Food coating

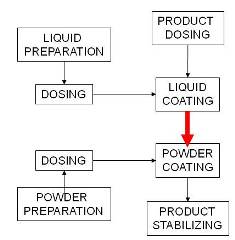

Coating is a process that consists of applying a liquid or a powder into the surface of an edible product to convey new (usually sensory) properties.

There are many similarities between coating processes and numerous examples of technology transfer to and from the food industry.

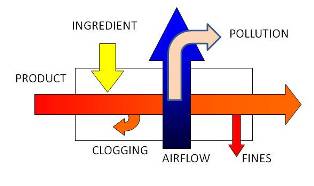

It consists mostly in setting the product particles in motion and simultaneously applying the coating ingredient in a certain pattern to expose one to the other.

It relies on an array of principles: entrapping a molecule inside a matrix, chemical bonding, and polymerisation.

Mere mechanical movement is not adequate and sufficient to fulfill the proper coating of minute particles.

Coating conveys functional properties, such as particle separation (oiled dry fruit, shredded cheese), antioxidant effect (fruit cubes), or a barrier effect [water migration between a layer of ice cream and a biscuit (cookie) or against moisture loss of chewing gum].

Parameters affecting the system are listed by origin: This first set of criteria governs the choice of the coating ingredient.

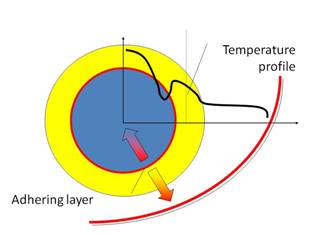

The influence of some phenomena and their parameters is critical: crystallisation, water removal (drying), glass transition, viscosity, or surface tension.

For example, fat will tend to set preferably on a cool product if the system wall is kept at a higher temperature.

Test results can be immediately evaluated (visual aspect) but are preferably assessed by careful measures : to allow monitoring, to agree on commissioning, to certify conformity with customer requirements.