Fracture

Fracture is the appearance of a crack or complete separation of an object or material into two or more pieces under the action of stress.

[2] If a ductile material reaches its ultimate tensile strength in a load-controlled situation,[Note 1] it will continue to deform, with no additional load application, until it ruptures.

The statistics of fracture in random materials have very intriguing behavior, and was noted by the architects and engineers quite early.

Brittle fracture typically involves little energy absorption and occurs at high speeds—up to 2,133.6 m/s (7,000 ft/s) in steel.

In amorphous solids, by contrast, the lack of a crystalline structure results in a conchoidal fracture, with cracks proceeding normal to the applied tension.

The fracture strength (or micro-crack nucleation stress) of a material was first theoretically estimated by Alan Arnold Griffith in 1921: where: – On the other hand, a crack introduces a stress concentration modeled by Inglis's equation[7] where: Putting these two equations together gets Sharp cracks (small

Recently, scientists have discovered supersonic fracture, the phenomenon of crack propagation faster than the speed of sound in a material.

Rapid loading, low temperature, and triaxial stress constraint conditions may cause ductile materials to fail without prior deformation.

The extensive plasticity causes the crack to propagate slowly due to the absorption of a large amount of energy before fracture.

[9][10] Because ductile rupture involves a high degree of plastic deformation, the fracture behavior of a propagating crack as modelled above changes fundamentally.

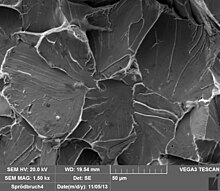

The microvoids nucleate at various internal discontinuities, such as precipitates, secondary phases, inclusions, and grain boundaries in the material.

[11] As local stress increases the microvoids grow, coalesce and eventually form a continuous fracture surface.

Fracture under local uniaxial tensile loading usually results in formation of equiaxed dimples.

Failures caused by shear will produce elongated or parabolic shaped dimples that point in opposite directions on the matching fracture surfaces.

Finally, tensile tearing produces elongated dimples that point in the same direction on matching fracture surfaces.

On the other hand, with brittle fracture, cracks spread very rapidly with little or no plastic deformation.

By performing the compact tension and three-point flexural tests, one is able to determine the fracture toughness through the following equation: Where: To accurately attain

and sharpening this notch to better emulate a crack tip found in real-world materials.

Ceramics and inorganic glasses have fracturing behavior that differ those of metallic materials.

[14] However, as demonstrated by Faber and Evans, fracture toughness can be predicted and improved with crack deflection around second phase particles.

Due to how ceramics are manufactured and processed, there are often preexisting defects in the material introduce a high degree of variability in the Mode I brittle fracture.

The lower platform can also be assumed to have finite rigidity, so that local deformation of the platform occurs wherever springs fail and the surviving neighbor fibers have to share a larger fraction of that transferred from the failed fiber.

[5] Though brittle fracture is less common than other types of failure, the impacts to life and property can be more severe.

Since there are so few actual problems with closed-form analytical solutions, numerical modelling has become an essential tool in fracture analysis.

There are literally hundreds of configurations for which stress-intensity solutions have been published, the majority of which were derived from numerical models.

The J integral and crack-tip-opening displacement (CTOD) calculations are two more increasingly popular elastic-plastic studies.

[17] Some of the traditional methods in computational fracture mechanics, which were commonly used in the past, have been replaced by newer and more advanced techniques.

The newer techniques are considered to be more accurate and efficient, meaning they can provide more precise results and do so more quickly than the older methods.

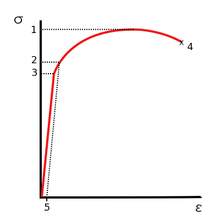

- Ultimate tensile strength

- Yield strength

- Proportional limit stress

- Fracture

- Offset strain (typically 0.2%)