Fused quartz

Depending on manufacturing processes, impurities will restrict the optical transmission, resulting in commercial grades of fused quartz optimized for use in the infrared, or in the ultraviolet.

The low coefficient of thermal expansion of fused quartz makes it a useful material for precision mirror substrates or optical flats.

[7] Many optical applications of fused quartz exploit its wide transparency range, which can extend well into the ultraviolet and into the near-mid infrared.

Some high-power vacuum tubes used silica envelopes whose good transmission at infrared wavelengths facilitated radiation cooling of their incandescent anodes.

In the semiconductor industry, its combination of strength, thermal stability, and UV transparency makes it an excellent substrate for projection masks for photolithography.

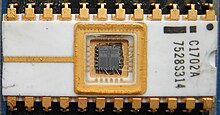

EPROMs are recognizable by the transparent fused quartz (although some later models use UV-transparent resin) window which sits on top of the package, through which the silicon chip is visible, and which transmits UV light for erasing.

The material behaves in a predictable way and allows the optical fabricator to put a very smooth polish onto the surface and produce the desired figure with fewer testing iterations.

Fused quartz can be metallised and etched for use as a substrate for high-precision microwave circuits, the thermal stability making it a good choice for narrowband filters and similar demanding applications.

Fused quartz as an industrial raw material is used to make various refractory shapes such as crucibles, trays, shrouds, and rollers for many high-temperature thermal processes including steelmaking, investment casting, and glass manufacture.

Translucent fused-quartz tubes are commonly used to sheathe electric elements in room heaters, industrial furnaces, and other similar applications.

"UV grade" synthetic fused silica (sold under various tradenames including "HPFS", "Spectrosil", and "Suprasil") has a very low metallic impurity content making it transparent deeper into the ultraviolet.

"Infrared grade" fused quartz (tradenames "Infrasil", "Vitreosil IR", and others), which is electrically fused, has a greater presence of metallic impurities, limiting its UV transmittance wavelength to around 250 nm, but a much lower water content, leading to excellent infrared transmission up to 3.6 μm wavelength.