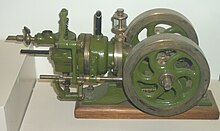

Gas engine

Generally in modern usage, the term gas engine refers to a heavy-duty industrial engine capable of running continuously at full load for periods approaching a high fraction of 8,760 hours per year, unlike a gasoline automobile engine, which is lightweight, high-revving and typically runs for no more than 4,000 hours in its entire life.

[2] However, the Lenoir engine suffered from a low power output and high fuel consumption.

In 1867 Otto patented his improved design and it was awarded the Grand Prize at the 1867 Paris World Exhibition.

This atmospheric engine worked by drawing a mixture of gas and air into a vertical cylinder.

When the piston has risen about eight inches, the gas and air mixture is ignited by a small pilot flame burning outside, which forces the piston (which is connected to a toothed rack) upwards, creating a partial vacuum beneath it.

The work is done when the piston and toothed rack descend under the effects of atmospheric pressure and their own weight, turning the main shaft and flywheels as they fall.

Its advantage over the existing steam engine was its ability to be started and stopped on demand, making it ideal for intermittent work such as barge loading or unloading.

The best-known builder of gas engines in the United Kingdom was Crossley of Manchester, who in 1869 acquired the United Kingdom and world (except German) rights to the patents of Otto and Langen for the new gas-fuelled atmospheric engine.

Manufacturers of gas engines include Hyundai Heavy Industries, Rolls-Royce with the Bergen-Engines AS, Kawasaki Heavy Industries, Liebherr, MTU Friedrichshafen, INNIO Jenbacher, Caterpillar Inc., Perkins Engines, MWM, Cummins, Wärtsilä, INNIO Waukesha, Guascor Energy , Deutz, MTU, MAN, Scania AB, Fairbanks-Morse, Doosan, Eaton (successor to another former large market share holder, Cooper Industries), and Yanmar.

INNIO Jenbacher and Waukesha are the only two companies whose engines are designed and dedicated to gas alone.

Connected to either natural gas from the public utility or propane from on-site storage tanks, these generators can be arranged for automatic starting upon power failure.

Liquefied natural gas (LNG) engines are expanding into the marine market, as the lean-burn gas engine can meet the new emission requirements without any extra fuel treatment or exhaust cleaning systems.

Use of engines running on compressed natural gas (CNG) is also growing in the bus sector.

The main source of energy is the gas-air mixture but it is ignited by the injection of a small volume of diesel fuel.

For example, some manufactures have mechanically driven pumps whereas other use electrically driven pumps to drive engine cooling water, and the electrical usage can sometimes be ignored giving a falsely high apparent efficiency compared to the direct drive engines.

Cooling is required to remove excessive heat, as overheating can cause engine failure, usually from wear, cracking or warping.