Ground glass joint

Ground glass joints are used in laboratories to quickly and easily fit leak-tight apparatus together from interchangeable commonly available parts.

For example, a round bottom flask, Liebig condenser, and oil bubbler with ground glass joints may be rapidly fitted together to reflux a reaction mixture.

The first number represents the outer diameter (OD) in millimeters at the widest point of the inner (male) joint.

[5] If the angle standard taper fittings make with glassware is not perfectly set, the glass is extremely rigid and brittle, presenting a fracture risk on some setups.

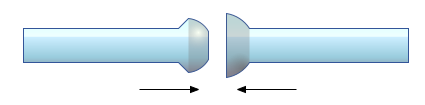

A ball and socket joining method allows some flexibility in the mating angles of the pieces being joined, which can be particularly important with heavy flasks or long pieces of glassware that would otherwise be difficult to support and potentially snap under bending loads.

A common example of this is the collection flask on a rotary evaporator, whose weight increases significantly as it fills.

They can also be found as the necks on pilot plant production flasks, where large volumes and masses are present, and on some Schlenk lines, where the long spans of fine glass benefit from a little flexibility between pieces.

Flat joints are mostly seen on large columns and reaction vessels, although they are used in some smaller applications such as flasks with removable lids.

Bottles and jars in which chemicals are sold, transported, and stored usually have threaded openings facing the outside and matching non-glass caps or lids.

To prevent a joint from separating during a reaction process, various types of plastic or metal clips or springs can be used to secure the two sides together.

As glassware temperatures are recommended up to 250 °C, care needs to be taken that clips made from this material are not being used to hold glass together that will get this hot.

PTFE joint clips are sometimes used, as its recommended temperature peak matches that of most practical chemistry work.

The same is true of using Krytox and chemically resistant Molykote (PTFE thickened, fluoro based) oils and greases for glassware seals.

Lower grades of stainless steel are still rapidly attacked in the presence of the corrosive gases and the clips themselves are often as expensive as PTFE.

Some glassware features barbs (devil's horns, Viking helmet) protruding from the sides of the tapers.

The use of springs is beneficial when dealing with positive pressures, as they apply enough force for the glass to operate, but will open the taper if an unexpected excursion occurs.

For situations where the simple spring action of metal wires or plastic is not strong enough or are not convenient for other reasons, screwed clamps can be used to hold joints together.

This helps provide a good seal and prevents the joint from seizing, allowing the parts to be disassembled easily.