Hand pump

[1] Hand pumps are commonly used in developing countries for both community supply and self-supply of water and can be installed on boreholes or hand-dug wells.

Modern hand-operated community pumps are considered the most sustainable low-cost option for safe water supply in resource-poor settings, often in rural areas in developing countries.

A hand pump opens access to deeper groundwater that is often not polluted and also improves the safety of a well by protecting the water source from contaminated buckets.

However, scarcity of spare parts for these type of pumps in some regions of Africa has diminished their utility for these areas.

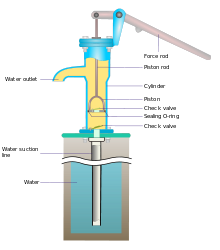

[6] One manufacturer who illustrated this product from the late 1880s onwards into the early 20th century was Goulds Manufacturing Co.[7] Where it is necessary to raise water to a height above that to which a suction or lift pump will operate effectively (about 7 metres), or to raise the pressure so that it will exit a nozzle with a strong force, such as through a fire hose, a force pump may be used.

The difference is however that after the water is sucked through the lower valve (as a result of raising the piston that is attached to the handle), its means of exit is via a pipe or nozzle in the side of the main cylinder.

The water, once it has been drawn up above the lower valve and trapped there, is forced out the exit when the piston or plunger is pushed down again on the next stroke.

Using this principle, very simple pumps with plastic or rubber bulb with flap valve at each end are used for emptying fuel or water cans into tanks.

Thus where the levels are correct large volumes of liquid such as swimming pools can be emptied with very little effort and no expensive energy use.

[17] With this in mind, manufacturers of water pumps, like those produced by GOAZ Development in Malaysia, have a wide range of potential customers: governments, non- governmental organizations, women's groups, community groups and other organizations of various types interested to developing access to groundwater.

[15] VLOM, meaning Village Level Operation and Maintenance, is a term first used during the UNDP and World Bank Rural Water Supply Hand Pumps Project.

The project brought approximately 230 rural villages inclined towards periods of drought, and 228,000 people access to safe water.

[20] The Mali Rural Supply Project did positively affect the longevity of hand pumps by doing the following: establishing local depots of spare parts, training individuals to maintain pumps, scheduling inspections from officials of the project, forming local committees and recruiting volunteers.

In communities reliant on groundwater, through a borehole or well, the utilization of a bucket and rope system has hygienic issues.

[20] In addition, animal contamination and the mixing of groundwater and surface water were factors in sub- par sanitation.

[20] In addition, many depots withdrew support after the donated inventory ran out, the contracts given to consultants eventually closed, and maintenance was not kept up to a high standard.

[20] A June 2008 study, conducted by the World Bank, Review of Effectiveness of Rural Water Supply Schemes in India, showed that approximately 45 percent of rural piped water projects focused on breakdown maintenance instead of scheduled maintenance.

[21] Whether or not a project to use hand pumps in a developing country is an affordable alternative certainly depends on who or what organization pays the bill.

Materials readily available, like a rope covered in chicken fat or leather belt, can be used to ensure maintenance.