Heat flux sensor

Some instruments are actually single-purpose heat flux sensors, like pyranometers for solar radiation measurement.

More exotic applications include estimation of fouling on boiler surfaces, temperature measurement of moving foil material, etc.

The total heat flux is composed of a conductive, convective and radiative part.

An example of a sensor sensitive to radiative as well as convective heat flux is a Gardon or Schmidt–Boelter gauge, used for studies of fire and flames.

Typically, two or three sensors are buried in the ground around a meteorological station at a depth of around 4 cm below the surface.

In a world ever more concerned with saving energy, studying the thermal properties of buildings has become a growing field of interest.

One of the starting points in these studies is the mounting of heat flux sensors on walls in existing buildings or structures built especially for this type of research.

Heat flux sensors mounted to building walls or envelope component can monitor the amount of heat energy loss/gain through that component and/or can be used to measure the envelope thermal resistance, R-value, or thermal transmittance, U-value.

Two major differences however are the fact that the thermal properties of a wall generally do not change (provided its moisture content does not change) and that it is not always possible to insert the heat flux sensor in the wall, so that it has to be mounted on its inner or outer surface.

When the heat flux sensor has to be mounted on the surface of the wall, one has to take care that the added thermal resistance is not too large.

[5] The measurement of the heat exchange of human beings is of importance for medical studies, and when designing clothing, immersion suits and sleeping bags.

[6] A difficulty during this measurement is that the human skin is not particularly suitable for the mounting of heat flux sensors.

For this reason, whenever a high level of quality assurance of the measurement is required, it can be recommended to use a self-calibrating sensor.

Examples of these environments are aluminium smelting, solar concentrators, coal fired boilers, blast furnaces, flare systems, fluidized beds, cokers,... Special heat flux solutions are used in highly transient temperatures changes.

These gauges called Thermocouple MCT, allow the measurement of highly transient surface temperatures.

For example, they are typical for testing wind tunnel models in impulse facilities, the change of the cylinder wall temperature during one cycle of a combustion engine, all types of industrial applications, and research-oriented work where the registration of highly transient temperatures is of importance.

The design of the gauges is such that during a typical time period of about 10 ms, the requirements of a body of semi-infinite thickness are fulfilled.

General advantages of thermopiles are their stability, low ohmic value (which implies little pickup of electromagnetic disturbances), good signal-noise ratio and the fact that zero input gives zero output.

For better understanding of heat flux sensor behavior, it can be modeled as a simple electrical circuit consisting of a resistance,

The sensor schematically given in the above figure would for example also be sensitive to heat flows from left to right.

This type of behavior will not cause problems as long as fluxes are uniform and in one direction only.

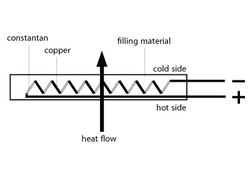

To promote uniformity of sensitivity, a so-called sandwich construction as shown in the figure to the left can be used.

The purpose of the plates, which have a high conductivity, is to promote the transport of heat across the whole sensitive surface.

If during application, there is non-uniform behavior of the sensor or the flux, this will result in different outputs of the two parts.

In order to do in-situ measurements, the user must be provided with the correct calibration constant

The sensitivity is primarily determined by the sensor construction and operation temperatures, but also by the geometry and material properties of the object that is measured.

If the sensor is mounted onto a surface and is exposed to convection and radiation during the expected applications, the same conditions should be taken into account during calibration.

By applying a known voltage on and current through the heater, a controlled heat flux is provided which can be used to calculate the new sensitivity.

In order to avoid errors caused by long response times, one should use sensors with low value of

The sensor response time equation above holds as long as the cold joints are at a constant temperature.