High-temperature operating life

This test stresses the IC at an elevated temperature, high voltage and dynamic operation for a predefined period of time.

This method ages all IC's building blocks to allow relevant failure modes to be triggered and implemented in a short reliability experiment.

A precise multiplier, known as the Acceleration Factor (AF) simulates long lifetime operation.

The AF represents the accelerated aging factor relative to the useful life application conditions.

For effective HTOL stress testing, several variables should be considered: A detailed description of the above variables, using a hypothetical, simplified IC with several RAMs, digital logic, an analog voltage regulator module and I/O ring, together with the HTOL design considerations for each are provided below.

The time unit is relative to the toggling frequency, and is usually limited by the HTOL setup to be in the range of 10–20Mhz.

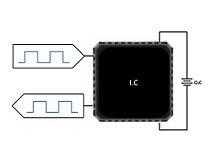

Reliability engineers strive to toggle as many as possible transistors for each time unit of measure.

The power and the self-heating of the digital portion of the IC are evaluated and the device's aging estimated.

This trend complicates reliability engineers' work because (usually) the analog portion of the chip dissipates higher power relative to the other IC elements.

This higher power may generate hot spots and areas of accelerated aging.

Reliability engineers must understand the power distribution on the chip and align the aging so that it is similar for all elements of an IC.

In reality, there may be additional analog modules e.g. PMIC, oscillators, or charge pumps.

The degrees of freedom for aligning the aging magnitude of analog parts is usually the duty-cycle, external load values and voltage stress.

As previously mentioned, the main aim of the HTOL is aging the samples by dynamic stress at elevated voltage and/or temperature.

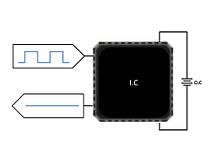

During the HTOL operation, we need to assure that the IC is active, toggling and constantly functioning.

At the same time, we need to know at what point the IC stops responding, these data are important for calculating price reliability indices and for facilitating the FA.

There are three types of monitoring: According to JEDEC standards, the environmental chamber should be capable of maintaining the specified temperature within a tolerance of ±5 °C throughout while parts are loaded and unpowered.

Today's environmental chambers have better capabilities and can exhibit temperature stability within a range of ±3 °C throughout.

Low power ICs can be stressed without major attention to self-heating effects.

However, due to technology scaling and manufacturing variations, power dissipation within a single production lot of devices can vary by as much as 40%.

An elevated voltage provides additional acceleration and can be used to increase effective device hours or achieve an equivalent life point.

There are several AFv models: AFtemp is the acceleration factor due to changes in temperature and is usually based on the Arrhenius equation.

The total acceleration factor is the product of AFv and AFtemp The reliability test duration assures the device's adequate lifetime requirement.

The challenge for new reliability assessment and qualification systems is determining the relevant failure mechanisms to optimize sample size.

All test samples shall be fabricated, handled, screened and assembled in the same way as during the production phase.

For example, with an activation energy of 0.7e V, Tj of 135 °C and Tuse of 55 °C the equivalent checkpoints will be at 29, 102, 303 and 606 hours.

If testing exceeds the recommended time window, additional stress should be applied according to the table below:[2] The merit number is the outcome of statistical sampling plans.

Sampling plans are inputted to SENTENCE, an audit tool, to ensure that the output of a process meets the requirements.

Chi Squared/2 is the probability estimation for number of failures at α and ν Acceleration Factor from the Arrhenius equation =

Mean Time to Failure = MTTF Where the Acceleration Factor from the Arrhenius equation is: