Hydrophobic silica

In this process, plasma polymerized 1,7-octadiene (ppOD) (related to the diene hydrocarbons) is used to deposit polymer films onto the silica particles.

Using low specific energy plasma conditions, the ppOD films chemically render the silica particles hydrophobic.

The process takes a few seconds in terms of reaction time, and there's no requirement for heating and chemically treating the particles after development.

The initial silica nanoparticles are in an amorphous crystalline phase and the solvent is composed of trimethylsilyl chloride (TMCS) and ethyl alcohol.

Upon entry into the furnace, the ethyl alcohol evaporates from the colloid precursor, allowing self-assembly to occur between the silica particles and the surface treating agent, TMCS.

[8] Hydrophobic silica is used to solve technical problems in a number of products including, but not limited to, paints, inks, adhesives, plastics, coatings, toners, defoamers, silicone rubber, sealants, cosmetics, food additives, polyester resins, cable gels, and greases.

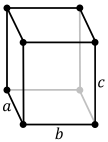

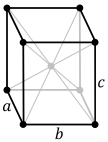

It's often manufactured as both single and multiphase composites in order to enhance properties such as dispersion, stability behavior, resistance to water, and functionality.

Hydrophobic silica has been added to aerogels to increase their ability to adsorb organic pollutants without disrupting the network structure.