Laser trimming

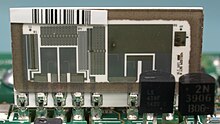

One of the most common applications uses a laser to burn away small portions of resistors, raising their resistance value.

A lateral cut in the resistor material by the laser narrows or lengthens the current flow path and increases the resistance value.

One type of passive trimmer uses a pressure chamber to enable resistor trimming in a single run.

In many applications, the end user of the product would prefer not to have potentiometers, as they can drift, be mis-adjusted or develop noise.

Therefore, manufacturers determine the needed resistance or capacitance values by measurement and calculation methods and afterwards solder the suitable component into the final PCB; this approach is called "Select on Test" (SOT) and is quite labor-intensive.

The achieved accuracy can be higher, the procedure can be automated, and the long-term stability is better than with potentiometers and at least as good as with SOT components.