Liquid-crystal polymer

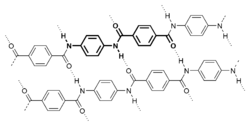

The chemical structure of this aramid consists of linearly substituted aromatic rings linked by amide groups.

A high number of LCPs, produced in the 1980s, displayed order in the melt phase analogous to that exhibited by nonpolymeric liquid crystals.

LCPs can be melt-processed on conventional equipment at high speeds with excellent replication of mold details.

[8] Polar and bowlic LCPs, which have unique properties and potential applications[clarification needed], have not been widely produced for industrial purposes.

The mesogen cores of the polymers will aggregate into different mesophases: nematics, cholesterics, smectics and compounds with highly polar end groups.

LCPs can be roughly divided into two subcategories based on the mechanism of aggregation and ordering, but the distinction is not rigidly defined.

[12] This type of LCPs forms liquid crystals due to their rigid chain conformation but not only the aggregation of mesogen cores.

Because of the rigid structure, strong solvent is needed to dissolve the lyotropic main chain polymers.

As the concentration varies above the critical volume fraction, the liquid crystal generated may be packed in different structures.

Lyotropic side chain LCPs such as alkyl polyoxyethylene surfactants attached to polysiloxane polymers may be used in personal care products like liquid soap.

[3] Besides the display application, research has focused on other interesting properties such as its special thermally and photogenerated macroscale mechanical responses, which means they can be good actuators.

They have been studied for use as lightweight energy absorbers, with potential applications in helmets, body armor, vehicle bumpers, using multi-layered, tilted beams of LCE, sandwiched between stiff supporting structures.

Poly(dydrosiloxane) is mixed with a monovinyl-functionalized liquid crystalline monomer, a multifunctional vinyl crosslinker, and catalyst.

During the first crosslinking step or shortly after that, orientation is introduced into the mesogen cores of the gel with mechanical alignment methods.

[16] A unique class of partially crystalline aromatic polyesters based on p-hydroxybenzoic acid and related monomers, liquid-crystal polymers are capable of forming regions of highly ordered structure while in the liquid phase.

Liquid-crystal polymers come in a variety of forms from sinterable high temperature to injection moldable compounds.

They resist stress cracking in the presence of most chemicals at elevated temperatures, including aromatic or halogenated hydrocarbons, strong acids, bases, ketones, and other aggressive industrial substances.

Environments that deteriorate the polymers are high-temperature steam, concentrated sulfuric acid, and boiling caustic materials.

Polar and bowlic LCPs are ferroelectrics, with reaction time order-of-magnitudes smaller than that in conventional LCs and could be used to make ultrafast switches.

[17] Because of their various properties, LCPs are useful for electrical[18] and mechanical parts, food containers, and any other applications requiring chemical inertness and high strength.